Product Information

I. Application Areas

Water Treatment Equipment: In the gate opening and closing mechanisms of sewage treatment plants and the sliding guide rails of water quality monitoring equipment, all-plastic linear bearings can withstand corrosion from sewage and chemical agents (such as disinfectants, acids, and alkalis), preventing jamming or failure caused by rust in metal bearings.

Marine Engineering: For moving parts on ship decks (such as gangways and hatch covers) and guiding mechanisms of underwater detection equipment, the all-plastic material resists saltwater corrosion and microbial fouling, eliminating the need for frequent anti-corrosion maintenance.

Chemical Equipment: Guide rails for mixing devices in acid and alkali storage tanks and piston rod guides for chemical transfer pumps can adapt to the corrosive gas and liquid environments of chemical plants.

Office Automation Equipment: For paper feeding guide rails in printers, scanning frame sliding mechanisms in photocopiers, and cutter feed guides in shredders, all-plastic bearings are lightweight (40%-60% lighter than metal bearings of the same size), reducing the load on the drive motor, and have extremely low friction noise (operating noise ≤40dB), meeting the quiet requirements of office environments.

Small Precision Instruments: For the stage movement mechanisms of electron microscopes and the optical path adjustment guide rails of laser engraving machines, the self-lubricating properties of all-plastic bearings (some containing lubricants such as graphite and molybdenum disulfide) reduce friction, ensuring motion accuracy (positioning error ≤0.01mm), and avoiding the "creeping" phenomenon of metal bearings.

Textile Machinery: In the yarn guide rods of spinning machines and the heddle frame sliding mechanisms of weaving machines, all-plastic linear bearings will not scratch delicate yarns and can withstand the lint and dust environment of textile workshops, reducing failures caused by fiber entanglement.

Gardening and Agricultural Equipment: For the blade adjustment guide rails of lawnmowers and the sprinkler head movement mechanisms of irrigation equipment, all-plastic bearings require no lubrication (self-lubricating properties) and can adapt to outdoor environments exposed to wind and rain, reducing maintenance frequency. Furniture and Daily Necessities: Drawer slides, piston rod guides for lifting chairs, and treadmill belt adjustment mechanisms. All-plastic bearings are low-cost, easy to install, and meet the wear resistance requirements for everyday light-load use (with a service life of over 100,000 cycles).

II. Advantages of Use

Strong Chemical Resistance: All-plastic materials (such as PTFE) have extremely high resistance to acids, bases, salts, organic solvents, and other chemical substances, and will not seize or fail due to rust or chemical corrosion like metal bearings.

Unaffected by Moisture and Salt Spray: In marine engineering and outdoor water conservancy equipment, they can withstand the effects of seawater salt spray and rainwater immersion, eliminating the need for additional anti-corrosion coatings or regular maintenance, significantly reducing equipment failure rates.

No Additional Lubrication Required: Some all-plastic bearing materials contain solid lubricants such as graphite, molybdenum disulfide, and PTFE powder, resulting in a low friction coefficient (usually between 0.04 and 0.1), enabling "lifetime lubrication-free" operation.

No Risk of Oil Contamination: In fields with extremely high cleanliness requirements, such as food processing and medical equipment, all-plastic bearings will not contaminate products or the environment due to lubricating oil leakage, meeting stringent standards such as FDA and GMP.

Excellent Electrical Insulation Performance: Plastic is a good insulator, non-conductive and non-magnetic. In electronic equipment (such as circuit board testing machines), Cost-effective: The raw material and processing costs of all-plastic bearings (which can be formed in one step through injection molding) are far lower than those of metal bearings, especially in mass production, where costs can be reduced by 30%-50%. For light-load, non-precision applications (such as furniture slides and agricultural irrigation equipment), they are an economical and practical choice.

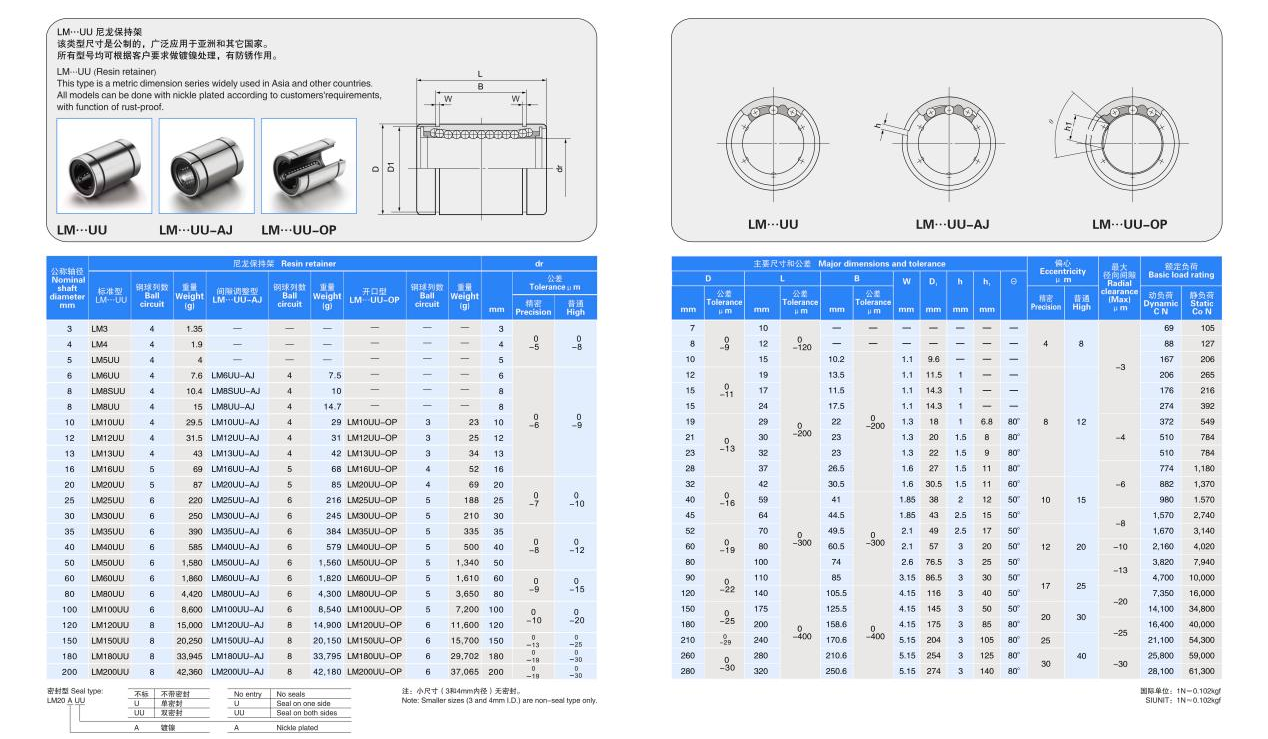

Product Specifications