Product Information

I. Application Areas

1. Automated Production Lines and Intelligent Manufacturing Equipment: Assembly line transfer mechanisms (such as workpiece gripping and handling modules), automated assembly machines (such as electronic component insertion guides), guide components for belt/chain conveyor lines, and linear drive modules for robot end effectors.

2. Heavy Machinery and Processing Equipment: Worktable guide sliders for gantry milling machines/machining centers, slider drive mechanisms for large bending machines, support and guide components for heavy-duty conveyor rollers, and material pushing slides for mining machinery.

3. Precision Instruments and Testing Equipment: Moving axis sliders for coordinate measuring machines (CMMs), lens adjustment guides for optical inspection equipment (such as CCD vision inspection), guide components for semiconductor wafer handling equipment, and sliding mechanisms for medical imaging equipment (such as CT beds).

4. Logistics and Warehousing Automation Equipment: Intelligent sorting machines (such as slider modules for cross-belt sorters), lifting/translating guides for automated storage and retrieval systems, steering wheel guide sliders for AGVs (Automated Guided Vehicles), and parcel pushing sliders for express sorting lines.

II. Advantages

1. High-precision guidance, meeting the needs of precise motion:

When used with precision guide rails, the positioning accuracy (repeatability error) of the box-type slider can reach ±0.005mm, and the travel parallelism is ≤0.01mm/m, meeting the "micron-level" accuracy requirements of automated assembly and precision machining;

The gap between the rolling elements and the guide rail can be adjusted through pre-tensioning (such as light pre-tensioning, medium pre-tensioning) to eliminate motion clearance and avoid "reverse crawling" (i.e., backlash error during reverse motion), which is especially suitable for equipment requiring frequent direction changes (such as sorting machines). 2. Excellent structural protection, adaptable to complex working conditions

Most box-type linear guides come with a built-in sealing structure (such as rubber sealing rings at both ends and side dust shields), which effectively prevents dust, cutting fluid, oil, and other impurities from entering the inside of the guide, reducing wear on the rolling elements and extending their service life (service life can reach over 10,000 hours under normal working conditions);

3. Superior shock absorption and damping, improving motion stability

The box structure of the linear guide has certain "elastic buffering" characteristics. Combined with the point contact/line contact method of the rolling elements, it can absorb small vibrations generated during motion (such as motor start-stop shocks and load fluctuations), preventing vibration from being transmitted to the workpiece or precision components (such as optical lenses);

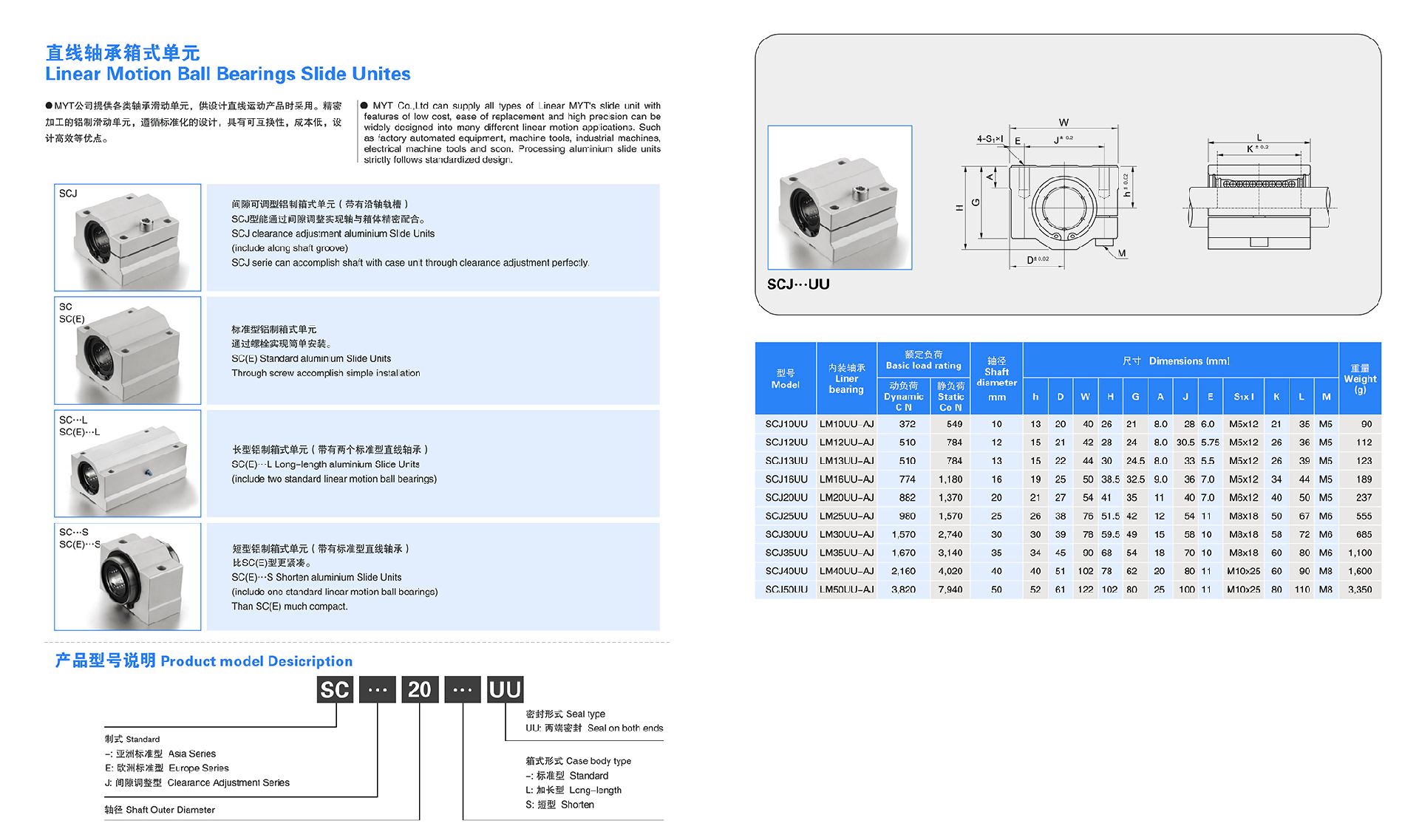

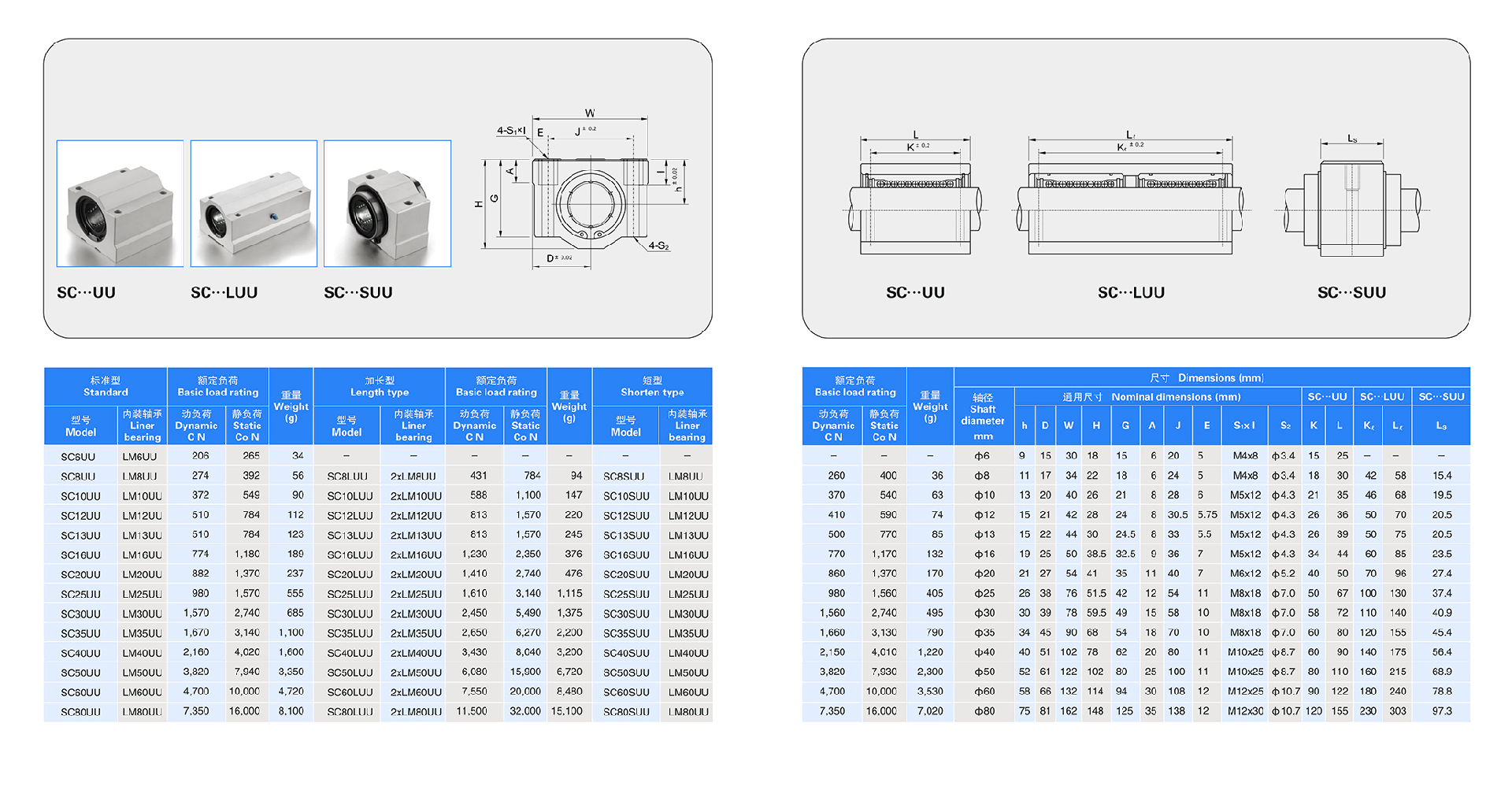

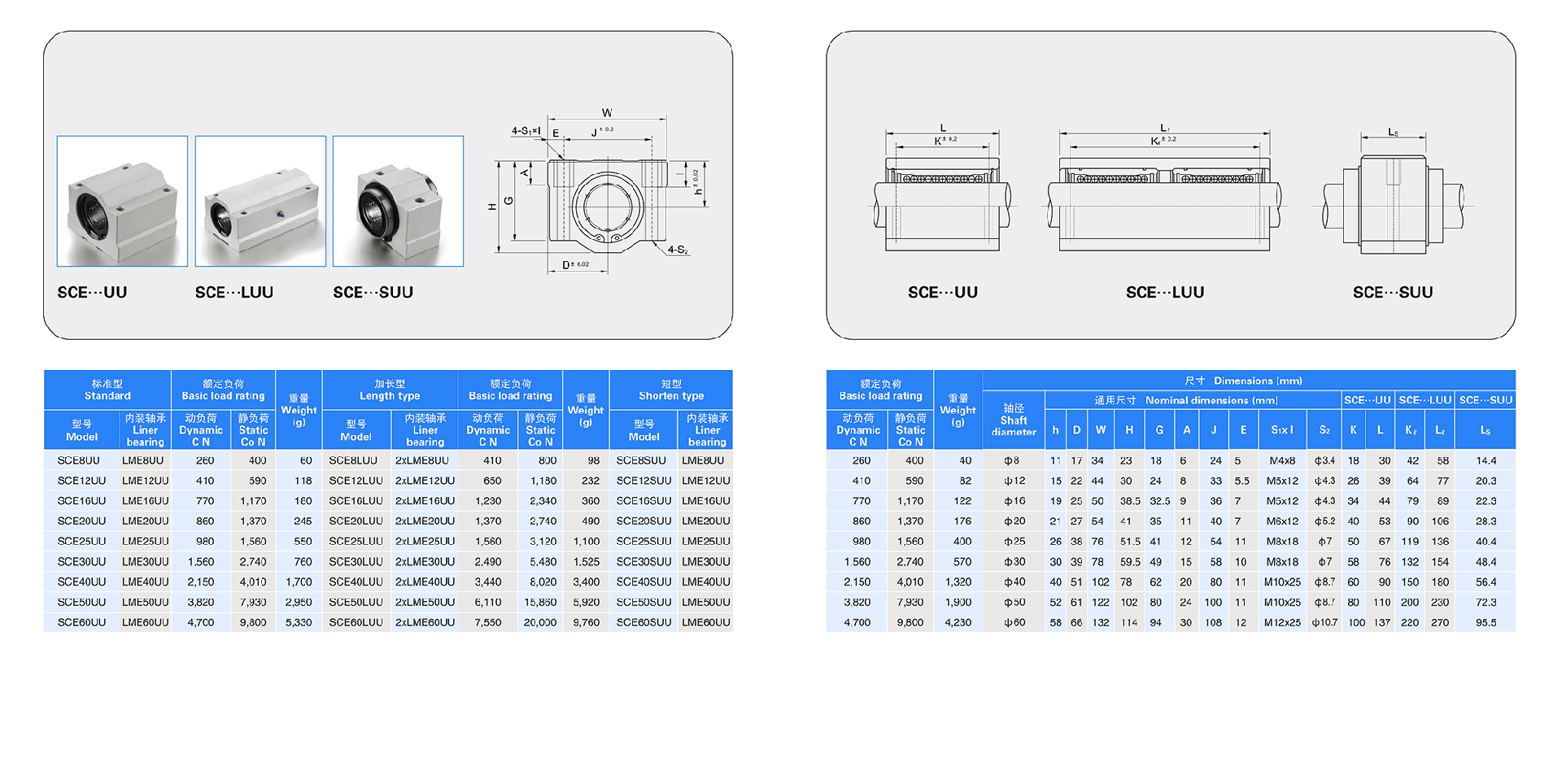

Product Specifications