Product Information

I. Application Areas

1. Automated Production Lines and Robots: SCARA/Delta joints, transfer and sorting, requiring high rigidity and rapid installation.

2. Precision Machine Tools and Woodworking Machinery: X/Y slides, tool holder feeding, pursuing high precision and rigidity.

3. Electronics and Semiconductor Equipment: Wafer transfer, dispensing/placement, emphasizing cleanliness, low friction, and repeatable positioning.

4. Medical and Life Sciences: Imaging equipment platforms, analytical instruments, emphasizing low vibration and stable operation.

5. Packaging and Food Machinery: Labeling, filling, conveying, requiring compact structure and easy maintenance.

6. Printing and Textile Machinery: Paper/fabric feeding mechanisms, requiring high speed and low friction.

II. Advantages

1. Higher Rigidity and Anti-Tilting: The guide groove enhances radial and tilting rigidity, suppressing swaying, suitable for heavy loads and high dynamic conditions.

2. Convenient Installation and Space Saving: The round flange can be directly bolted, used with a cylindrical optical axis, shortening the debugging cycle.

3. Low Friction and High Sensitivity: Low rolling friction coefficient, smooth start and stop, beneficial for high speed and micron-level resolution.

4. Strong Standardization and Interchangeability: Universal interface, easily available spare parts, low maintenance costs.

5. Compact Structure and Cost-Effective: Compared to square guide rail systems, it saves space and cost, suitable for small and medium-sized equipment.

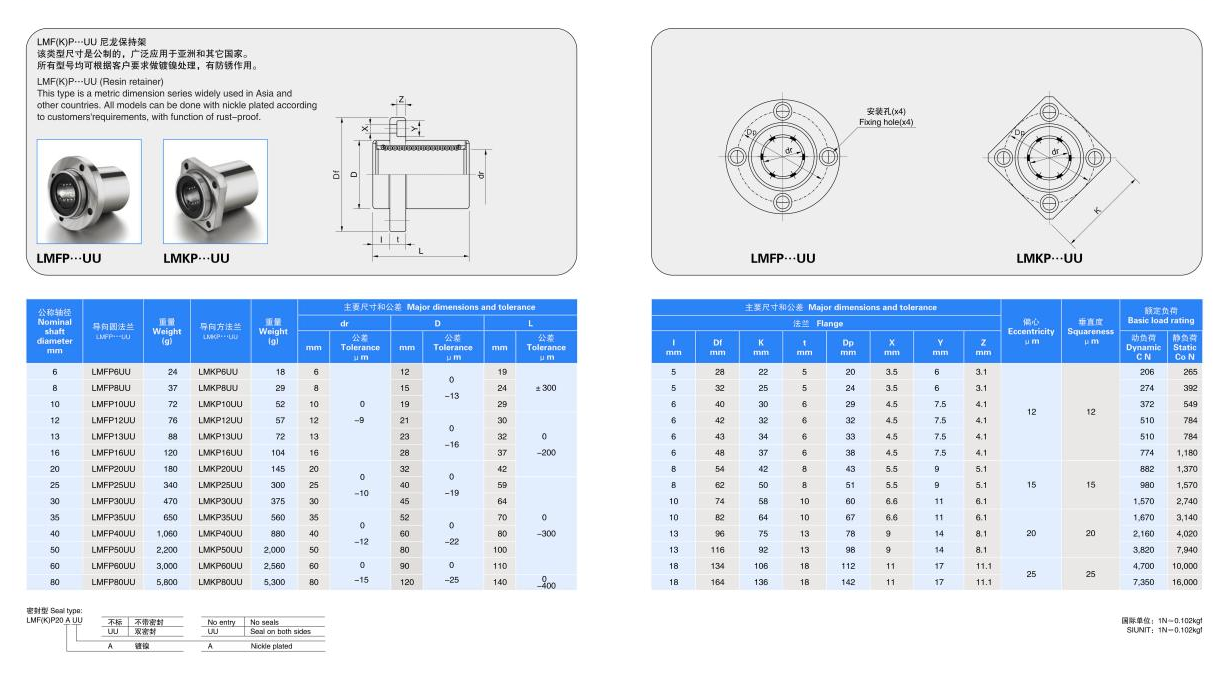

Product Specifications