Product Information

I. Application Areas

Automotive Chassis Systems: Guide rollers in suspension structures. The roller needle bearings contact the metal track via a curved outer ring, bearing the radial load from the vehicle body weight while reducing frictional resistance during suspension movement.

Belt Conveyors and Chain Drives: Idler rollers and tensioning pulleys in conveyors. Roller needle bearings replace traditional sliding bearings, reducing operating noise (≤65dB) and energy consumption (friction coefficient ≤0.003), suitable for heavy-duty applications such as mining and ports.

Agricultural Machinery: Track wheels and guide wheels of tractors and harvesters. Roller needle bearings are adapted to muddy field environments (some models have sealed structures), bearing the tension and impact of the tracks.

Construction Engineering Machinery: Drum support rollers of concrete mixer trucks, adapted to the continuous rotation of the drum (speed 5-15 r/min), with high load capacity to match the weight of the tank and materials.

Automated Production Lines: Guide rollers in precision assembly lines (such as for conveying and positioning bearings and electronic components). The flat outer ring ensures smooth workpiece transport, and the low friction characteristics are suitable for high-speed operation (linear speed up to 1-5 m/s).

Metallurgical Equipment: Roll support rollers in rolling mills, bearing the enormous radial pressure during the rolling process (up to several hundred kN). The high strength of the needles (materials are mostly high-carbon chromium bearing steel GCr15) resists impact and high temperatures (≤150℃).

II. Advantages

Excellent Impact Resistance: The needles are made of high-strength bearing steel (such as GCr15), with a hardness of HRC60-65 after quenching and tempering, able to withstand instantaneous impact loads (such as the impact force during braking of construction machinery or stamping by a press), reducing deformation or fracture caused by impact.

Lightweight and Compact Size: Roller needle bearings have no inner ring (or the inner ring is integrated with the shaft), and the needles directly contact the shaft, greatly simplifying the structure. The radial dimension (difference between outer and inner diameter) is 30%-50% smaller than ball bearings or roller bearings with the same load capacity. Rolling friction replaces sliding friction: The rolling motion of the needle rollers results in an extremely low friction coefficient (typically 0.001-0.003, far lower than the 0.1-0.3 of sliding bearings). In high-speed or high-frequency motion scenarios (such as conveyor rollers and printing press guide rollers), this significantly reduces energy consumption (energy saving rate can reach 10%-20%) while also reducing heat generation.

High motion stability: The needle rollers are evenly separated by a cage, preventing mutual friction. Combined with precisely machined outer rings and shafts, this achieves low vibration (vibration acceleration ≤1mm/s²) and low noise (operating noise ≤60dB), making them suitable for equipment requiring high stability (such as medical instrument conveying mechanisms).

Resistance to eccentric loads and overturning: When subjected to a certain axial eccentric load or overturning moment, the line contact of the needle roller assembly can distribute stress through multi-point support, making it less prone to jamming or localized wear due to eccentric loads compared to point-contact bearings. For example, the end rollers of a cantilevered robotic arm can stably withstand eccentric loads through roller needle bearings.

Product Specifications

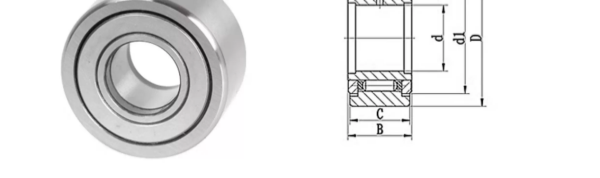

NATR type support roller bearing | |||||||||

model | Main dimensions (mm) | Basic rated load | Maximum rotational speed | weight (kg) | |||||

d | D | B | C | d1 | move kN | quiet kN | |||

NATR5PP | 5 | 16 | 12 | 11 | 12 | 3.1 | 3 | 22000 | 0.014 |

NATV5PP | 5 | 16 | 12 | 11 | 12 | 4.5 | 6.3 | 8500 | 0.015 |

NATR6PP | 6 | 19 | 12 | 11 | 14 | 3.6 | 3.7 | 20000 | 0.02 |

NATV6PP | 6 | 19 | 12 | 11 | 14 | 5.7 | 8.7 | 7000 | 0.021 |

NATR8PP | 8 | 24 | 15 | 14 | 19 | 4.5 | 5.4 | 13000 | 0.041 |

NATV8PP | 8 | 24 | 15 | 14 | 19 | 8.6 | 12 | 5500 | 0.042 |

NATR10PP | 10 | 30 | 15 | 14 | 23 | 6.1 | 7.8 | 11000 | 0.064 |

NATV10PP | 10 | 30 | 15 | 14 | 23 | 10.9 | 17 | 4500 | 0.065 |

NATR12PP | 12 | 32 | 15 | 14 | 25 | 6.6 | 9.8 | 9000 | 0.071 |

NATV12PP | 12 | 32 | 15 | 14 | 25 | 11.8 | 19 | 3900 | 0.072 |

NATR15PP | 15 | 35 | 19 | 18 | 27 | 10.5 | 17.5 | 7000 | 0.103 |

NATV15PP | 15 | 35 | 19 | 18 | 27 | 16 | 32.5 | 3400 | 0.105 |

NATR17PP | 17 | 40 | 21 | 20 | 32 | 11.8 | 19.4 | 6000 | 0.144 |

NATV17PP | 17 | 40 | 21 | 20 | 32 | 19.6 | 37 | 2900 | 0.152 |

NATR20PP | 20 | 47 | 25 | 24 | 37 | 17.5 | 29.8 | 4900 | 0.246 |

NATV20PP | 20 | 47 | 25 | 24 | 37 | 25.8 | 57 | 2600 | 0.254 |

NATR25PP | 25 | 52 | 25 | 24 | 42 | 19.5 | 36.5 | 3600 | 0.275 |

NATV25PP | 25 | 52 | 25 | 24 | 42 | 29 | 69.6 | 2100 | 0.285 |

NATR30PP | 30 | 62 | 29 | 28 | 51 | 31 | 57.5 | 2600 | 0.47 |

NATV30PP | 30 | 62 | 29 | 28 | 51 | 45.5 | 104 | 1700 | 0.481 |

NATR35PP | 35 | 72 | 29 | 28 | 58 | 34.5 | 67.5 | 2000 | 0.635 |

NATV35PP | 35 | 72 | 29 | 28 | 58 | 50.8 | 109.5 | 1400 | 0.647 |

NATR40PP | 40 | 80 | 32 | 30 | 66 | 47 | 91.5 | 1700 | 0.805 |

NATV40PP | 40 | 80 | 32 | 30 | 66 | 64 | 139 | 1300 | 0.89 |

NATR45PP | 45 | 85 | 32 | 30 | 72 | 49.1 | 98 | 1500 | 0.91 |

NATV45PP | 45 | 85 | 32 | 30 | 72 | 66 | 153 | 1100 | 0.935 |

NATR50PP | 50 | 90 | 32 | 30 | 76 | 50.5 | 106 | 1200 | 0.96 |

NATV50PP | 50 | 90 | 32 | 30 | 76 | 69.5 | 187 | 1000 | 0.99 |

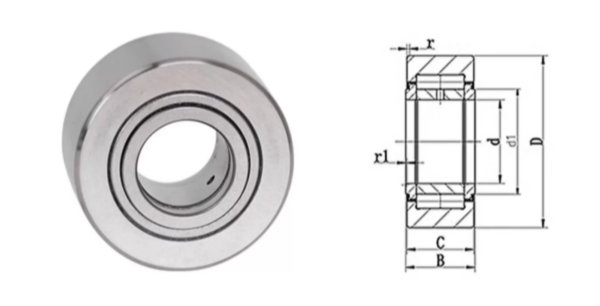

NUT R type support roller bearing | |||||||||

Model | Main dimensions (mm) | Basic rated load | Maximum rotational speed | Weight(kg) | |||||

d | D | B | C | d1 | move kN | quiet kN | |||

NUTR15 | 15 | 35 | 19 | 18 | 20 | 20.5 | 24.5 | 6500 | 0.099 |

NUTR1542 | 15 | 42 | 19 | 18 | 20 | 20.5 | 24.5 | 6500 | 0.158 |

NUTR17 | 17 | 40 | 21 | 20 | 22 | 21.8 | 28.5 | 5500 | 0.147 |

NUTR1747 | 17 | 47 | 21 | 20 | 22 | 21.8 | 28.5 | 5500 | 0.22 |

NUTR20 | 20 | 47 | 25 | 24 | 27 | 36.9 | 48.9 | 4200 | 0.245 |

NUTR2052 | 20 | 52 | 25 | 24 | 27 | 36.9 | 48.9 | 4200 | 0.321 |

NUTR25 | 25 | 52 | 25 | 24 | 31 | 40.8 | 58.5 | 3400 | 0.281 |

NUTR2562 | 25 | 62 | 25 | 24 | 31 | 40.8 | 58.5 | 3400 | 0.45 |

NUTR30 | 30 | 62 | 29 | 28 | 38 | 56.8 | 77.5 | 2600 | 0.465 |

NUTR3072 | 30 | 72 | 29 | 28 | 38 | 56.8 | 77.5 | 2600 | 0.697 |

NUTR35 | 35 | 72 | 29 | 28 | 44 | 63 | 91 | 2100 | 0.63 |

NUTR3580 | 35 | 80 | 29 | 28 | 44 | 63 | 91 | 2100 | 0.836 |

NUTR40 | 40 | 80 | 32 | 30 | 51 | 87.9 | 108 | 1600 | 0.816 |

NUTR4090 | 40 | 90 | 32 | 30 | 51 | 87.9 | 108 | 1600 | 0.95 |

NUTR45 | 45 | 85 | 32 | 30 | 55 | 93.6 | 119 | 1400 | 0.883 |

NUTR45100 | 45 | 100 | 32 | 30 | 55 | 93.6 | 119 | 1400 | 1.396 |

NUTR50 | 50 | 90 | 32 | 30 | 60 | 98.9 | 140 | 1300 | 0.95 |

NUTR50110 | 50 | 110 | 32 | 30 | 60 | 98.9 | 140 | 1300 | 1.69 |

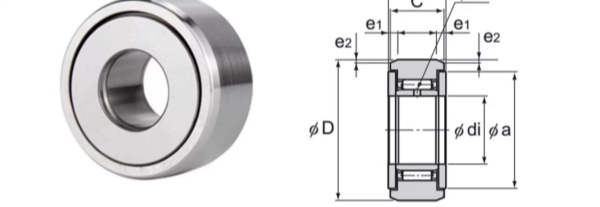

NAST type support roller bearing | ||||||||||||||

Model | Main dimensions (mm) | Basic rated load | Track surface load capacity | Maximum rotational speed min-1 | Weight (g) | |||||||||

d | D | B | C | a | e1 | e2 | oil hole d1 | C kN | Co kN | Cylindrical outer ring kN | Spherical outer ring kN | |||

NAST6ZZ | 6 | 19 | 14 | 13.8 | 14 | 2.5 | 0.8 | 1.5 | 4.12 | 4.55 | 3.53 | 1.37 | 20000 | 24.5 |

NAST8ZZ | 8 | 24 | 14 | 13.8 | 17.5 | 2.5 | 0.8 | 1.5 | 5.68 | 5.89 | 4.51 | 1.86 | 17000 | 39 |

NAST10ZZ | 10 | 30 | 16 | 15.8 | 23.5 | 2.5 | 0.8 | 2 | 9.7 | 9.67 | 6.86 | 2.45 | 15000 | 65 |

NAST12ZZ | 12 | 32 | 16 | 15.8 | 25.5 | 2.5 | 0.8 | 2 | 10.4 | 10.9 | 7.35 | 2.74 | 13000 | 75 |

NAST15ZZ | 15 | 35 | 16 | 15.8 | 29 | 2.5 | 0.8 | 2 | 12.3 | 14.3 | 8.04 | 3.14 | 10000 | 83 |

NAST17ZZ | 17 | 40 | 20 | 19.8 | 32.5 | 3 | 1 | 2 | 17.4 | 20.9 | 11.8 | 3.72 | 9500 | 135 |

NAST20ZZ | 20 | 47 | 20 | 19.8 | 38 | 3 | 1 | 2.5 | 19.2 | 24.5 | 13.8 | 4.61 | 8500 | 195 |

NAST25ZZ | 25 | 52 | 20 | 19.8 | 43 | 3 | 1 | 2.5 | 20.7 | 28.4 | 15.3 | 5.29 | 7000 | 225 |

NAST30ZZ | 30 | 62 | 25 | 24.8 | 50.5 | 4 | 1.2 | 3 | 30.3 | 45.4 | 22.1 | 6.66 | 5500 | 400 |

NAST35ZZ | 35 | 72 | 25 | 24.8 | 53.5 | 4 | 1.2 | 3 | 32.2 | 50.6 | 25.7 | 8.13 | 5000 | 550 |

NAST40ZZ | 40 | 80 | 26 | 25.8 | 61.5 | 4 | 1.2 | 3 | 35.7 | 61.6 | 30.3 | 9.31 | 4000 | 710 |

NAST45ZZ | 45 | 85 | 26 | 25.8 | 66.5 | 4 | 1.2 | 3 | 37.1 | 66.4 | 31.1 | 10.1 | 4000 | 760 |

NAST50ZZ | 50 | 90 | 26 | 25.8 | 76 | 4 | 1.2 | 3 | 38.7 | 71.8 | 34 | 11 | 3500 | 830 |