Product Information

I. Application Areas

1. Machine Tools and Precision Equipment: Spindle tailstock and feed screw support bearings for lathes and grinding machines. The flange edge directly contacts the equipment end face, limiting the axial movement of the bronze bushing and ensuring machining accuracy.

2. Construction Machinery and Heavy Machinery: Boom articulation points and turntable support shafts for excavators and cranes. The flange edge bears part of the axial force, working with the pivot pin to achieve multi-directional force balance and prevent the bronze bushing from shifting under impact.

Slider guide bushings for hydraulic presses and stamping machines. The flange is bolted to the equipment housing, providing secure fixing and facilitating quick disassembly and maintenance.

3. Automotive and Rail Transit: Input shaft bearings and steering knuckle kingpin bushings for automotive transmissions. The flange structure simplifies the assembly of the transmission housing or steering axle, while also bearing the axial force generated by gear meshing.

4. General Machinery and Light Industrial Equipment: Impeller shaft support bushings for water pumps and fans. The flange is bolted to the pump body/fan housing, preventing axial sliding of the bronze bushing during high-speed rotation (medium to low speed range).

5. Metallurgy and Mining Equipment: Roll bearing seats for rolling mills and eccentric shaft bushings for crushers. The flange structure bears the axial force during rolling or crushing, and, combined with heavy-duty copper alloy materials (such as aluminum bronze), is suitable for high-temperature and dusty environments.

II. Advantages

1. Precise Axial Positioning and Convenient Installation: The flange edge directly contacts the equipment end face (or is fixed with bolts), eliminating the need for additional locating rings, shaft shoulders, and other structures, simplifying equipment housing processing.

2. More Comprehensive Load-Bearing Capacity: In addition to bearing radial loads (the main function of the bronze bushing), the flange edge can directly bear a certain axial force (depending on the flange thickness and material strength), preventing axial force from causing the bronze bushing to shift or be damaged.

Combined with the high wear resistance of copper alloys (tin bronze, aluminum bronze, etc.), it can operate stably under working conditions with radial loads of 100MPa+ and axial loads of 30MPa+. 3. Enhanced Stability and Reliability: The rigid connection between the flange and the equipment reduces loosening of the bronze bushing under vibration and impact conditions, minimizing abnormal wear or equipment failure caused by displacement (such as in the articulation points of construction machinery).

For components that require frequent disassembly and reassembly (such as in machine tool maintenance), the flange structure facilitates positioning and resetting, ensuring assembly consistency.

4. Cost and Space Optimization: Compared to the combination of "ordinary bronze bushing + retaining ring," the integrated structure of the flanged bronze bushing reduces the number of parts, lowering procurement and assembly costs.

Product Specifications

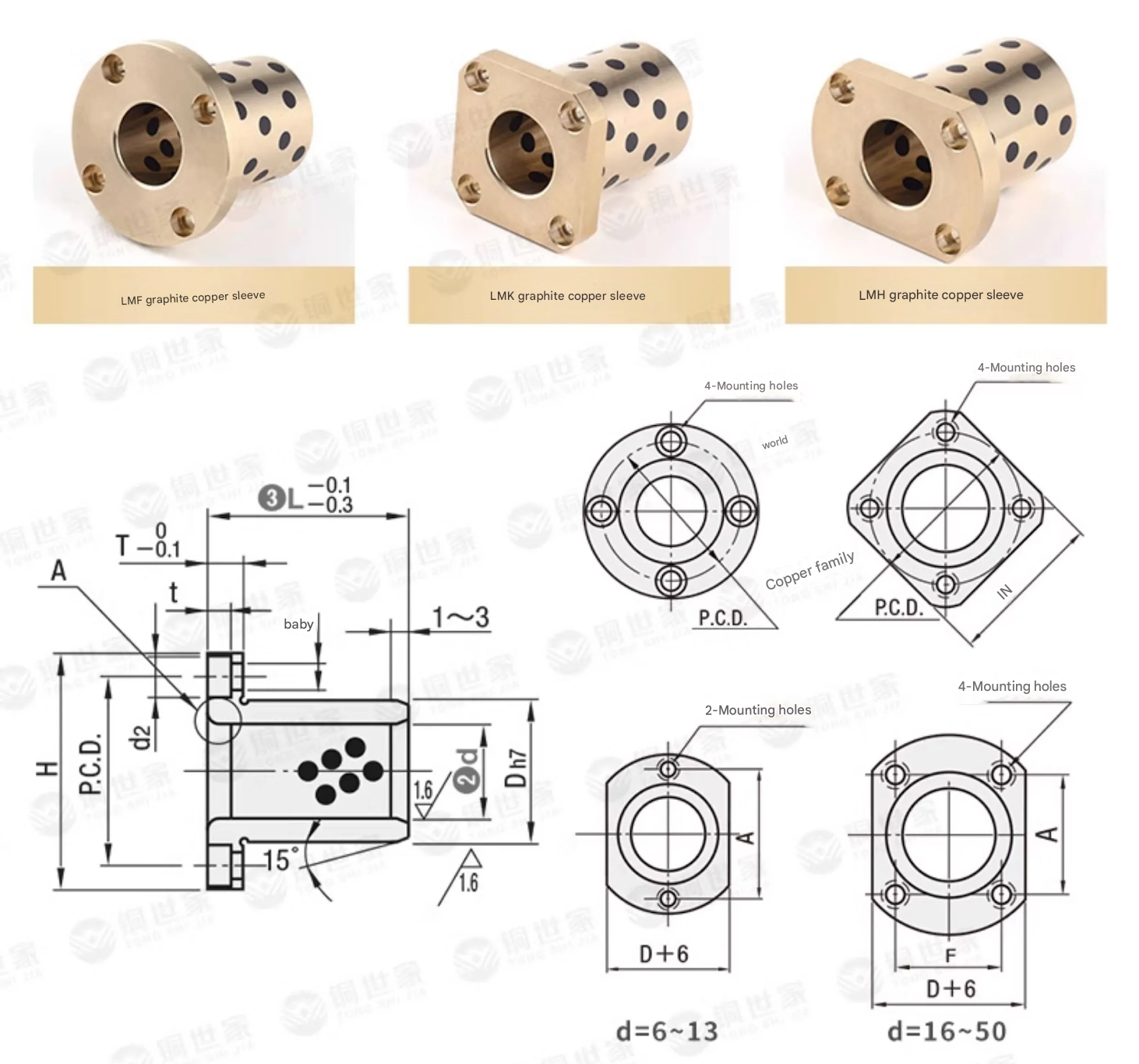

Linear Bearings - Graphite Copper Bushings (LMF Round Flange, LMK Square Flange, LMH Cut-Edge Flange) | ||||||||||||||

inner diameter | outer diameter | length | flange | Mounting holes | ||||||||||

d | Tolerance mm | D | Tolerance mm | L standard | L Lengthen | H | T | PCD | W | A | F | d1 | d2 | t |

6 | +0.0220 | 12 | 0 -0.018 | 19 | 35 | 28 | 5 | 20 | 22 | 20 | - | 3.5 | 6 | 3.1 |

8 | +0.0280 | 15 | 24 | 45 | 32 | 5 | 24 | 25 | 24 | - | 3.5 | 6 | 3.1 | |

10 | 19 | 0 -0.021 | 29 | 55 | 40 | 6 | 29 | 30 | 29 | - | 4.5 | 7.5 | 4.1 | |

12 | +0.0340 | 21 | 30 | 57 | 42 | 6 | 32 | 32 | 32 | - | 4.5 | 7.5 | 4.1 | |

13 | 23 | 32 | 61 | 43 | 6 | 33 | 34 | 33 | - | 4.5 | 7.5 | 4.1 | ||

16 | 28 | 37 | 70 | 48 | 6 | 38 | 37 | 31 | 22 | 4.5 | 7.5 | 4.1 | ||

20 | +0.0410 | 32 | 0 -0.025 | 42 | 80 | 54 | 8 | 43 | 42 | 36 | 24 | 5.5 | 9 | 5.1 |

25 | 40 | 59 | 112 | 62 | 8 | 51 | 50 | 40 | 32 | 5.5 | 9 | 5.1 | ||

30 | 45 | 64 | 123 | 74 | 10 | 60 | 58 | 49 | 35 | 6.6 | 11 | 6.1 | ||

35 | +0.0500 | 52 | 0 -0.030 | 70 | 135 | 82 | 10 | 67 | 64 | 55 | 38 | 6.6 | 11 | 6.1 |

40 | 60 | 80 | 151 | 96 | 13 | 78 | 75 | 64 | 45 | 9 | 14 | 8.1 | ||

50 | 80 | 100 | 192 | 116 | 13 | 98 | 92 | 80 | 56 | 9 | 14 | 8.1 | ||

60 | +0.0600 | 90 | 0 -0.030 | 110 | 209 | 134 | 18 | 112 | 106 | - | - | 11 | 17.5 | 10.8 |