Product Information

I. Application Areas

1. CNC Machine Tools: Used in the feed systems of CNC machine tools, such as supporting the linear motion of the worktable. The steel-outer, copper-inner linear bearings ensure high precision and stability during processing, meeting the manufacturing requirements of high-precision components.

2. Automation Equipment: Widely used in the conveying, testing, and assembly stages of automated production lines. For example, on electronic product assembly lines, they provide efficient, low-friction linear motion for the linear motion components of robotic arms, ensuring accurate and rapid assembly processes.

3. Medical Equipment: In medical equipment such as CT scanners and surgical robots, stable and precise linear motion control is required. Steel-outer, copper-inner linear bearings ensure precise adjustment and stable operation of the equipment. For example, surgical robots rely on them to achieve high-precision, smooth linear movements of instrument arms and other parts, assisting doctors in performing surgical procedures more accurately.

4. Automotive Industry: Applied in automotive seat adjustment systems and door slides, allowing seats to be adjusted smoothly and reliably in forward, backward, and up and down directions, and ensuring reliable opening and closing of car doors, guaranteeing convenience and ease of use.

II. Advantages:

1. Combination of High Strength and Wear Resistance: The outer steel sleeve has high strength and hardness, capable of withstanding large radial and axial loads, providing reliable support for the bearing. The inner copper material has good wear resistance, reducing friction with the shaft and extending the bearing's service life.

2. Good Self-Lubricating Performance: Copper itself has a certain degree of self-lubrication, especially when the copper alloy contains solid lubricants such as graphite. This allows steel-outer, copper-inner linear bearings to operate normally even in situations where frequent lubrication is difficult, reducing maintenance costs and difficulties.

3. Excellent Thermal Conductivity: Copper has good thermal conductivity. During bearing operation, it can dissipate the heat generated by friction in a timely manner, maintaining a lower operating temperature, reducing precision changes and part damage caused by thermal expansion, and improving the working stability and reliability of the bearing. 4. High Precision: The design and manufacturing of linear bearings ensure high precision. The steel outer shell and copper inner lining structure also helps maintain this precision. The rigidity of the steel sleeve reduces deformation of the bearing under load, thus ensuring that the cooperating shaft can achieve high-precision linear motion. This makes it suitable for equipment and applications requiring high precision.

Cost-Effective: Compared with traditional all-copper alloy bearings, the steel outer shell and copper inner lining linear bearings reduce the amount of copper used, thus lowering manufacturing costs while still meeting the performance requirements of most applications. This results in good cost-effectiveness.

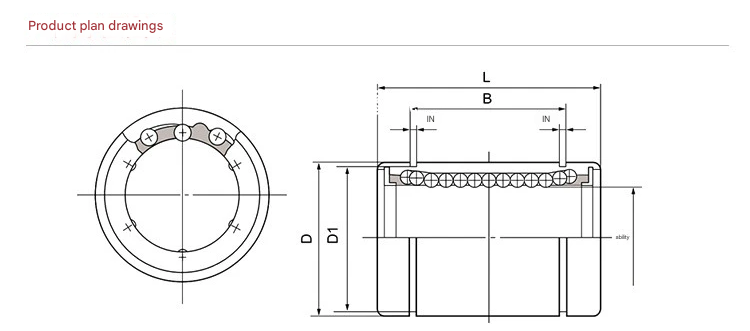

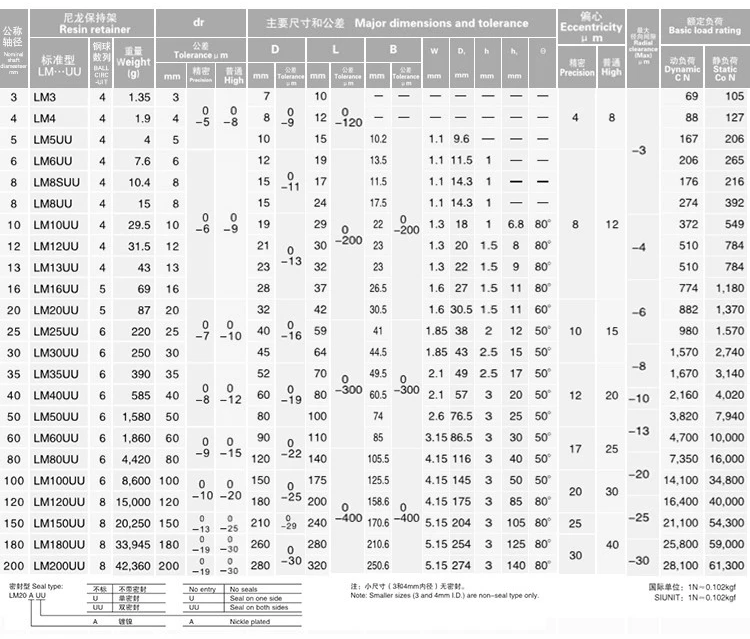

Product Specifications