Product Information

I. Application Areas

1. Automation Equipment: In automated production lines, such as conveyor systems and robotic arms, external steel, internal copper round flange linear bearings ensure precise and stable linear motion, improving production efficiency and product quality.

2. CNC Machine Tools: Used for linear motion support of worktables and tool holders in CNC machine tools, ensuring high-precision linear feed motion during machining, meeting the processing requirements of high-precision parts.

3. Precision Machinery: In precision machinery such as measuring instruments and optical equipment, these bearings provide precise linear guidance and support, ensuring the measurement and operation accuracy of the instruments and equipment.

4. Industrial Robots: Applied to the joints and end effectors of industrial robots, they help improve the motion accuracy and stability of the robots, enabling them to perform various complex actions more accurately.

5. Medical Equipment: Medical equipment such as CT scanners and surgical robots require precise linear motion control. External steel, internal copper round flange linear bearings ensure stable operation and precise adjustment of the equipment.

II. Advantages of Use

1. High Load Capacity: The round flange design increases the bearing's load-bearing area, allowing it to effectively handle axial and radial loads, significantly improving load capacity and ensuring the stable operation of the mechanical system.

2. Low Friction and Long Service Life: Utilizing the principle of rolling friction, compared to sliding friction, it has a lower friction coefficient, which helps reduce energy loss, improve the operating efficiency of the mechanical system, and extend the service life of the bearing.

3. Combination of High Strength and Wear Resistance: The outer steel sleeve has high strength and hardness, can withstand large loads, and provides reliable support for the bearing. The inner copper material has good wear resistance, reducing friction with the shaft and further extending the bearing's service life.

4. Good Self-Lubricating Performance: Copper itself has a certain degree of self-lubrication, especially when the copper alloy contains solid lubricants such as graphite, the self-lubricating performance is even better. This allows the bearing to operate normally in situations where frequent lubrication is difficult, reducing maintenance costs and difficulties.

5. Good Interchangeability: Linear bearings can be freely combined with standard guide shafts, offering good interchangeability, facilitating installation and replacement, and improving the maintainability of the equipment.

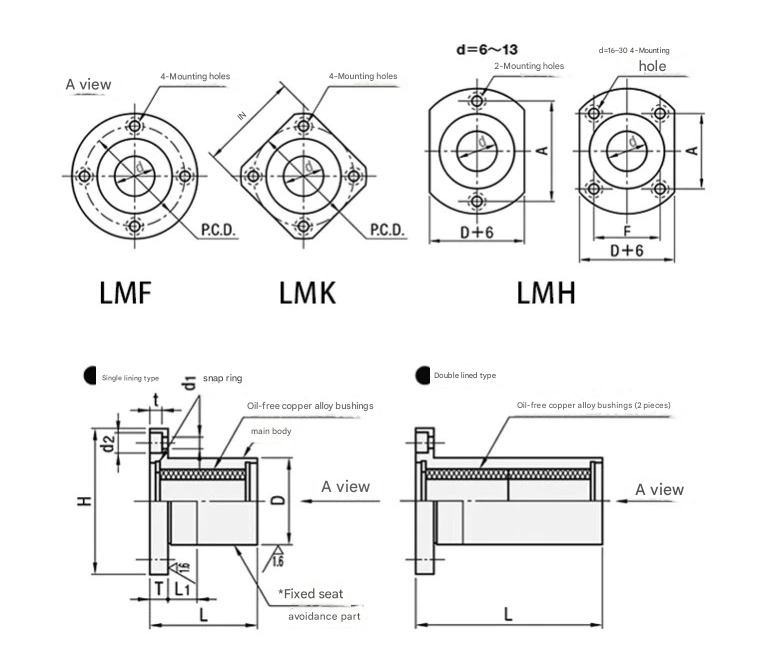

Product Specifications

model | Main dimensions | ||||||||||||

inner diameter | outer diameter | Length L | flange | Connecting hole | |||||||||

d | Tolerance mm | D | Tolerance mm | standard | Lengthen | H | W | T | PCD | d1 | d2 | t | |

(Round flange) LMF standard type, LMF...L extended type (Square flange) LMK standard type, LMK...L extended type | 6 | +0.0220 | 12 | 0 -0.018 | 19 | 35 | 28 | 22 | 5 | 20 | 3.5 | 6 | 3.1 |

8 | 15 | 24 | 45 | 32 | 25 | 5 | 24 | 3.5 | 6 | 3.1 | |||

10 | +0.0280 | 19 | 0 -0.021 | 29 | 55 | 40 | 30 | 6 | 29 | 4.5 | 7.5 | 4.1 | |

12 | 21 | 30 | 57 | 42 | 32 | 6 | 32 | 4.5 | 7.5 | 4.1 | |||

13 | +0.0340 | 23 | 32 | 61 | 43 | 34 | 6 | 33 | 4.5 | 7.5 | 4.1 | ||

16 | 28 | 37 | 70 | 48 | 37 | 6 | 38 | 4.5 | 7.5 | 4.1 | |||

20 | 32 | 0 -0.025 | 42 | 80 | 54 | 42 | 8 | 43 | 5.5 | 9 | 5.1 | ||

25 | +0.0410 | 40 | 59 | 112 | 62 | 50 | 8 | 51 | 5.5 | 9 | 5.1 | ||

30 | 45 | 64 | 123 | 74 | 58 | 10 | 60 | 6.6 | 11 | 6.1 | |||

35 | 52 | 0 -0.030 | 70 | 135 | 82 | 64 | 10 | 67 | 6.6 | 11 | 6.1 | ||

40 | +0.0500 | 60 | 80 | 154 | 96 | 75 | 13 | 78 | 9 | 14 | 8.1 | ||

50 | 80 | 100 | 192 | 116 | 92 | 13 | 98 | 9 | 14 | 8.1 | |||

60 | +0.0600 | 90 | 0 -0.040 | 110 | 209 | 134 | 106 | 18 | 112 | 11 | 18 | 11 | |