Product Information

I. Application Areas

1. Automated Production Lines and Conveying Equipment: In guide shaft supports and conveyor belt drive components, the square/rectangular structure of the flanged bearing allows for a tight fit with the equipment frame, suitable for flat mounting scenarios. It can stably support linear or reciprocating motion components (such as feeding mechanisms and lifting platforms), ensuring motion accuracy and load-bearing capacity.

2. CNC Machine Tools and Precision Machinery: Used in machine tool worktable guides, tool holder feeding systems, etc., the rigid structure of the flanged bearing reduces bearing vibration during high-speed motion. The outer steel sleeve bears radial loads, while the inner copper sleeve (when containing self-lubricating components) reduces friction, meeting the demands of precision machining for stability and low wear.

3. Engineering Machinery and Heavy Equipment:

4. Medical and Laboratory Equipment: Such as the sample transfer mechanism of blood analyzers and the guide rail support of precision pipetting equipment, the compact design of the flanged bearing saves installation space. The self-lubricating properties of the copper layer avoid frequent maintenance affecting equipment cleanliness, while ensuring smooth motion.

5. Textile and Printing Machinery: In the roller support of textile machines and the roller adjustment mechanism of printing presses, the flanged bearing can adapt to the square mounting surface of the equipment. The outer steel layer resists continuous vibration, and the inner copper layer reduces friction and wear between the shaft and bearing, extending the continuous operating time of the equipment.

II. Advantages

1. Strong Installation Adaptability: Compared to round flanges, flanged bearings (square/rectangular) are more suitable for flat, right-angle, or directional mounting scenarios. They can be securely fixed through multiple bolt holes, reducing loosening due to vibration, and are especially suitable for frame-type equipment structures.

2. High Strength and Load Capacity: The outer steel sleeve has high rigidity and hardness, and can withstand large radial and axial loads and impacts, suitable for heavy-duty or high-frequency motion equipment; the inner copper sleeve (such as tin bronze, lead bronze) buffers contact stress through its metallic properties, protecting the mating journal.

3. Cost and Performance Balance: Compared to all-copper bearings, the outer steel and inner copper structure reduces the amount of copper used, lowering costs; at the same time, it is more wear-resistant and has a lower friction coefficient than all-steel bearings, offering better cost-effectiveness in medium-load scenarios.

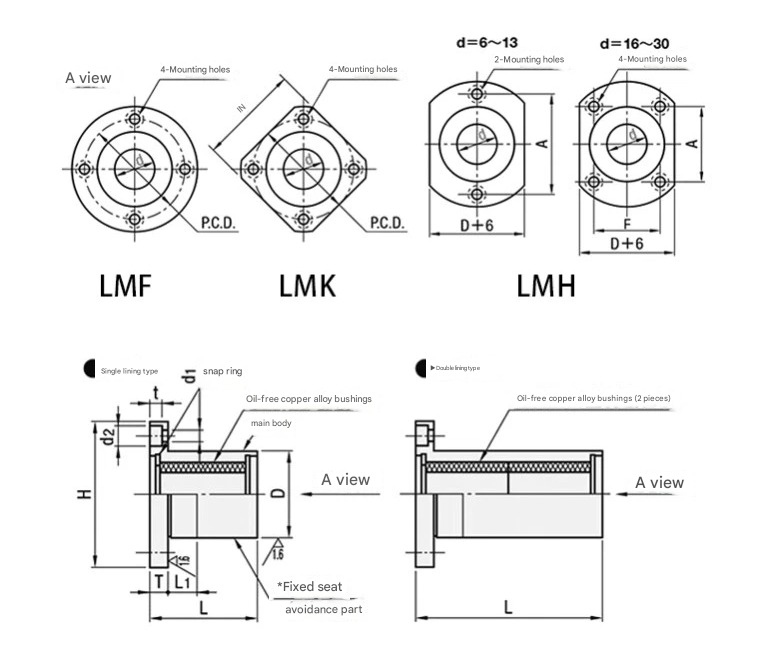

Product Specifications

model | Main dimensions | ||||||||||||

inner diameter | outer diameter | Length L | flange | Connecting hole | |||||||||

d | Tolerance mm | D | Tolerance mm | standard | Lengthen | H | W | T | PCD | d1 | d2 | t | |

(Round flange) LMF standard type, LMF...L extended type (Square flange) LMK standard type, LMK...L extended type | 6 | +0.0220 | 12 | 0 -0.018 | 19 | 35 | 28 | 22 | 5 | 20 | 3.5 | 6 | 3.1 |

8 | 15 | 24 | 45 | 32 | 25 | 5 | 24 | 3.5 | 6 | 3.1 | |||

10 | +0.0280 | 19 | 0 -0.021 | 29 | 55 | 40 | 30 | 6 | 29 | 4.5 | 7.5 | 4.1 | |

12 | 21 | 30 | 57 | 42 | 32 | 6 | 32 | 4.5 | 7.5 | 4.1 | |||

13 | +0.0340 | 23 | 32 | 61 | 43 | 34 | 6 | 33 | 4.5 | 7.5 | 4.1 | ||

16 | 28 | 37 | 70 | 48 | 37 | 6 | 38 | 4.5 | 7.5 | 4.1 | |||

20 | 32 | 0 -0.025 | 42 | 80 | 54 | 42 | 8 | 43 | 5.5 | 9 | 5.1 | ||

25 | +0.0410 | 40 | 59 | 112 | 62 | 50 | 8 | 51 | 5.5 | 9 | 5.1 | ||

30 | 45 | 64 | 123 | 74 | 58 | 10 | 60 | 6.6 | 11 | 6.1 | |||

35 | 52 | 0 -0.030 | 70 | 135 | 82 | 64 | 10 | 67 | 6.6 | 11 | 6.1 | ||

40 | +0.0500 | 60 | 80 | 154 | 96 | 75 | 13 | 78 | 9 | 14 | 8.1 | ||

50 | 80 | 100 | 192 | 116 | 92 | 13 | 98 | 9 | 14 | 8.1 | |||

60 | +0.0600 | 90 | 0 -0.040 | 110 | 209 | 134 | 106 | 18 | 112 | 11 | 18 | 11 | |