Product Information

I. Application Areas

1. Machine Tools and Precision Equipment: Feed screw support bearings for horizontal lathes, worktable guide sliders for milling machines. The square flange is fixed to the machine bed with bolts, and the bronze bushing supports the screw or guide shaft, limiting its axial movement (e.g., the lead screw bronze bushing in the carriage of a conventional lathe).

2. Textiles: Roller shaft support bushings for textile machines. The square flange is fixed to the machine frame, and the bronze bushing withstands the radial pressure during roller rotation while preventing axial displacement of the roller due to yarn tension (e.g., the doffer shaft bronze bushing in a carding machine).

3. Construction Machinery: Boom cylinder hinge shaft bushings for loaders. The square flange is fixed to the boom ear with high-strength bolts, and the bronze bushing bears the radial load of the hinge shaft, while the flange end face prevents axial displacement of the cylinder (aluminum bronze is often used for impact resistance).

4. Hydraulics: Valve core guide bushings for hydraulic valve blocks. The square flange is sealed and connected to the valve block with bolts. The bronze bushing ensures radial guidance of the valve core under high-pressure oil, and the flange limits the axial travel of the valve core (e.g., the valve core bronze bushing of a directional control valve).

II. Advantages

1. Precise axial positioning and strong anti-displacement capability: The square flange is rigidly connected to the base body with bolts, and the close fit between the flange end face and the base body strictly limits the axial displacement of the bronze bushing and shaft system (compared to flangeless bronze bushings, the axial positioning accuracy is improved by more than 30%), making it suitable for transmission scenarios sensitive to axial position (such as printing press rollers).

2. Balanced load-bearing capacity and good impact resistance: The large contact area of the square flange distributes the radial load to the base body, reducing local stress concentration on the base body (e.g., the flange at the hinge shaft of construction machinery can reduce wear on the ear). The integrated structure of the flange and the bronze bushing body (mostly cast or forged) is less prone to fracture under impact loads (compared to separate flange + bushing, the impact strength is increased by 20%-40%). 3. Sealing and Protection Optimization: Gaskets (such as rubber or copper gaskets) can be added to the flange face to achieve sealing of oil or gas in hydraulic and pneumatic equipment, preventing leakage (e.g., copper bushing flange sealing in hydraulic valve blocks).

The edges of the square flange can cover the clearance between the copper bushing and the mounting hole, reducing the intrusion of external dust and liquids (e.g., copper bushings in textile machine rollers, preventing cotton fibers from entering the friction surface).

Product Specifications

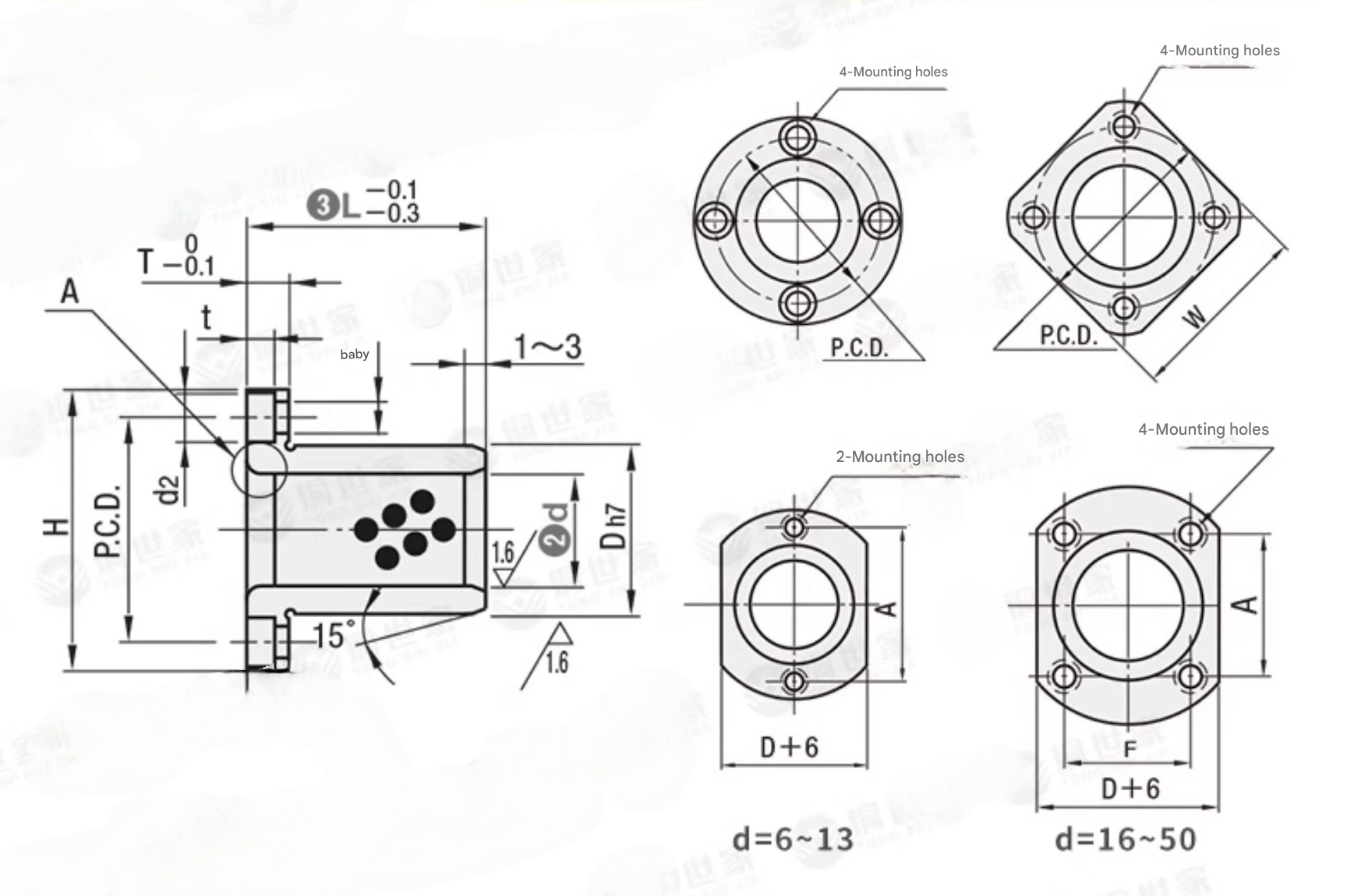

Linear Bearings - Graphite Copper Bushings (LMF Round Flange, LMK Square Flange, LMH Cut-Edge Flange) | |||||||||||||||||

inner diameter | outer diameter | length | flange | Mounting holes | |||||||||||||

d | Tolerance mm | D | Tolerance mm | L standard | L Lengthen | H | T | PCD | W | A | F | d1 | d2 | t | |||

6 | +0.0220 | 12 | 0 -0.018 | 19 | 35 | 28 | 5 | 20 | 22 | 20 | - | 3.5 | 6 | 3.1 | |||

8 | +0.0280 | 15 | 24 | 45 | 32 | 5 | 24 | 25 | 24 | - | 3.5 | 6 | 3.1 | ||||

10 | 19 | 0 -0.021 | 29 | 55 | 40 | 6 | 29 | 30 | 29 | - | 4.5 | 7.5 | 4.1 | ||||

12 | +0.0340 | 21 | 30 | 57 | 42 | 6 | 32 | 32 | 32 | - | 4.5 | 7.5 | 4.1 | ||||

13 | 23 | 32 | 61 | 43 | 6 | 33 | 34 | 33 | - | 4.5 | 7.5 | 4.1 | |||||

16 | 28 | 37 | 70 | 48 | 6 | 38 | 37 | 31 | 22 | 4.5 | 7.5 | 4.1 | |||||

20 | +0.0410 | 32 | 0 -0.025 | 42 | 80 | 54 | 8 | 43 | 42 | 36 | 24 | 5.5 | 9 | 5.1 | |||

25 | 40 | 59 | 112 | 62 | 8 | 51 | 50 | 40 | 32 | 5.5 | 9 | 5.1 | |||||

30 | 45 | 64 | 123 | 74 | 10 | 60 | 58 | 49 | 35 | 6.6 | 11 | 6.1 | |||||

35 | +0.0500 | 52 | 0 -0.030 | 70 | 135 | 82 | 10 | 67 | 64 | 55 | 38 | 6.6 | 11 | 6.1 | |||

40 | 60 | 80 | 151 | 96 | 13 | 78 | 75 | 64 | 45 | 9 | 14 | 8.1 | |||||

50 | 80 | 100 | 192 | 116 | 13 | 98 | 92 | 80 | 56 | 9 | 14 | 8.1 | |||||

60 | +0.0600 | 90 | 0 -0.030 | 110 | 209 | 134 | 18 | 112 | 106 | - | - | 11 | 17.5 | 10.8 | |||