Product Information

I. Application Areas

1. Precision Machinery: Spindle support and feed system ball screw nut seats in CNC machine tools. The closed structure prevents cutting fluid and metal chips from entering the mating clearance, ensuring transmission accuracy (e.g., the Z-axis guide rail slider bronze bushing in machining centers).

2. Hydraulics: Piston guide bushings and piston rod support bushings in hydraulic cylinders. The closed design ensures hydraulic oil sealing performance and prevents leakage (e.g., the clamping cylinder bronze bushing in injection molding machines).

3. Automotive and Construction Machinery: Camshaft bushings and balance shaft bushings in automotive engines. The closed structure withstands the periodic radial load during engine operation, while the thermal conductivity of copper helps dissipate heat (e.g., the camshaft bronze bushing in diesel engines). Gear shaft bushings in the transmission of loaders and bulldozers. The integral structure adapts to the lubricating oil environment inside the gearbox, preventing metal debris generated by gear meshing from entering the bushing clearance.

4. General Machinery: Impeller shaft bushings in water pumps and fans. The closed design prevents impurities in the medium (water, air) from wearing the journal. Using self-lubricating bronze bushings (containing graphite) reduces maintenance frequency (e.g., the drive shaft bronze bushing in deep well pumps).

5. Mining Equipment: Rolling mill roll bearing bushings and continuous casting machine crystallizer support bushings. Closed bronze bushings maintain structural stability in high-temperature and dusty environments, and withstand the radial pressure of the rolls (aluminum bronze material is often used for high-temperature wear resistance).

II. Advantages

1. Good Sealing and Protection Against Impurity Intrusion: The closed structure creates a relatively enclosed space in the mating clearance between the shaft and the bronze bushing, effectively preventing external dust and liquids (such as cutting fluid and hydraulic oil) from entering, thus reducing wear (e.g., guide bushings in hydraulic equipment).

2. Precise Positioning After Installation: After press-fitting or thermal fitting into the seat hole, the absence of open-end elastic deformation results in a tighter fit between the bronze bushing and the seat hole, leading to higher radial positioning accuracy (suitable for precision transmission components). 3. Excellent wear resistance and environmental adaptability: Copper alloys (such as tin bronze and aluminum bronze) inherently possess good wear resistance and anti-seizing properties. Even under brief periods of poor lubrication, they are less likely to seize with the journal (compared to steel bushings, they are more resistant to "dry friction").

Some copper alloys (such as aluminum bronze) have excellent corrosion resistance and can be used for extended periods in humid and mildly corrosive environments (such as marine equipment and chemical pumps).

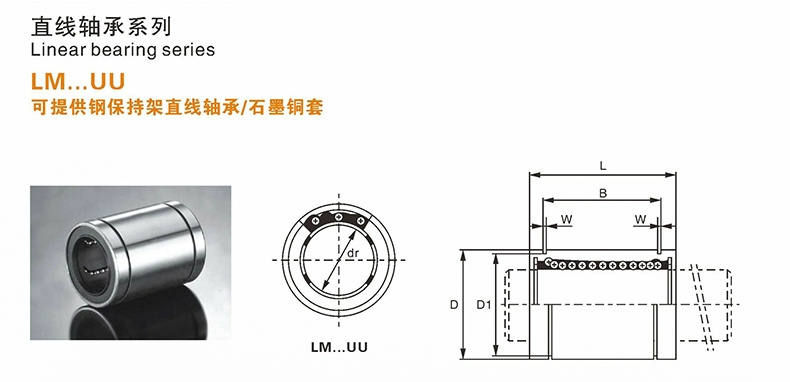

Product Specifications

model | Number of ball rows | Main dimensions | Radial runout | Basic rated load | weight (kg) | |||||||||||||

inner diameter | outer diameter | length | External stop groove | W | H | H1 | θ | move C(kg) | quiet Co(kg) | |||||||||

dr | tolerance | D | tolerance | L | tolerance | B | tolerance | D1 | ||||||||||

LM3 | 4 | 3 | 0 –0.008 | 7 | 0-0.009 | 10 | 0 -0.12 | 0 –0.20 | 0.008 | |||||||||

LM4 | 4 | 4 | 8 | 12 | 9 | 13 | 0.03 | |||||||||||

LM5 | 4 | 5 | 10 | 15 | 10.2 | 9.6 | 1.1 | 17 | 17 | 0.04 | ||||||||

LM6 | 4 | 6 | 0 –0.009 | 12 | 0 –0.011 | 17 | 0 –0.20 | 13.5 | 11.5 | 1.1 | 1 | 0.012 | 21 | 27 | 0.06 | |||

LM8S | 4 | 8 | 15 | 19 | 11.5 | 14.3 | 1.1 | 1 | 18 | 23 | 0.09 | |||||||

LM8 | 4 | 8 | 15 | 24 | 17.5 | 14.3 | 1.1 | 1 | 27 | 41 | 0.14 | |||||||

LM10 | 4 | 10 | 19 | 0 -0.013 | 29 | 22 | 18 | 1.3 | 1 | 6.8 | 80° | 38 | 56 | 0.28 | ||||

LM12 | 4 | 12 | 21 | 30 | 23 | 0-0.30 | 20 | 1.3 | 1.5 | 8 | 80° | 42 | 61 | 0.32 | ||||

LM13 | 4 | 13 | 23 | 32 | 23 | 22 | 1.3 | 1.5 | 9 | 80° | 52 | 79 | 0.38 | |||||

LM16 | 5 | 16 | 28 | 37 | 26.5 | 27 | 1.6 | 1.5 | 11 | 80° | 79 | 120 | 0.74 | |||||

LM20 | 5 | 20 |

0 –0.010 | 32 | 0 –0.016 | 42 | 30.5 | 30.5 | 1.6 | 1.5 | 11 | 60° | 0.015 | 88 | 140 | 0.80 | ||

LM25 | 6 | 25 | 40 | 59 | 0-0.30 | 41 | 38 | 1.85 | 2 | 12 | 50° | 100 | 160 | 2.06 | ||||

LM30 | 6 | 30 | 45 | 64 | 44.5 | 43 | 1.85 | 2.5 | 15 | 50° | 160 | 280 | 2.40 | |||||

LM35 | 6 | 35 | 0-0.012 | 52 | 0 –0.019 | 70 | 49.5 | 49 | 2.1 | 2.5 | 17 | 50° | 0.02 | 170 | 320 | 3.70 | ||

LM40 | 6 | 40 | 60 | 80 | 60.5 | 57 | 2.1 | 3 | 20 | 50° | 220 | 410 | 5.89 | |||||

LM50 | 6 | 50 | 80 | 100 | 74 | 76.5 | 2.6 | 3 | 25 | 50° | 390 | 810 | 14.80 | |||||

LM60 | 6 | 60 | 0-0.015 | 90 | 0-0.022 | 110 | 85 | 86.5 | 3.15 | 3 | 30 | 50° | 0.025 | 480 | 1020 | 17.50 | ||

LM80 | 6 | 80 | 0-0.022 | 120 | 0-0.04 | 140 | 0 –0.40 | 105.5 | 116 | 4.15 | 3 | 40 | 50° | 735 | 1600 | 44.20 | ||

LM100 | 6 | 100 | 150 | 175 | 125.5 | 145 | 4.15 | 3 | 50 | 50° | 0.03 | 1412 | 3480 | 86.00 | ||||