Product Information

I. Application Fields

Automated Production Lines: Used in the handling and transfer mechanisms of parts to achieve high-precision linear reciprocating motion of components such as sliders and push rods, such as the material feeding mechanisms of packaging machinery and the positioning devices of electronic component assembly lines.

Small Precision Machine Tools: Such as the feeding mechanisms of instrument lathes and coordinate boring machines, the flanged linear bearings can meet the high-precision requirements for micro-feed movements and reduce errors during motion.

Auxiliary Mechanisms of Machining Centers: Providing reliable linear motion support in mechanisms such as the extension and retraction of tool change arms in tool magazines and the movement of workpiece clamping devices, ensuring the accuracy of tool changes and clamping.

Semiconductor Wafer Processing Equipment: In the wafer transfer and positioning mechanisms, extremely high motion accuracy is required. Flanged linear bearings can be used with precision guide rails to achieve nanometer-level displacement control.

Electronic Component Packaging Equipment: Used in the worktable movement mechanisms of wire bonding machines and pick-and-place machines to ensure the precise placement of chips and components, improving packaging efficiency and quality.

Small Conveying Systems: Such as clean conveying lines in the food and pharmaceutical industries, flanged linear bearings can be used for guide wheels of conveyor belts and linear motion of pushing devices, meeting hygiene and low-maintenance requirements.

Warehousing and Logistics Equipment: Providing a compact installation structure and reliable linear motion in the moving parts of small stackers and sorting machines, saving equipment space and improving operating efficiency.

II. Advantages

Compact Structure Saves Installation Space: The flanged design integrates the bearing outer ring and the mounting flange, eliminating the need for additional mounting bases or fixing components. It can be directly bolted to the equipment panel, greatly simplifying the installation structure.

High Motion Accuracy: The bearing uses a precision ball or roller structure internally, combined with a hardened bearing sleeve and shaft, to achieve low-friction, high-rigidity linear motion. The motion clearance is small, and the repeatability accuracy can reach the micron level.

Balanced Load Capacity: Strong radial load capacity, and the flange structure can withstand a certain axial load (such as the impact force during equipment start and stop), adapting to complex working conditions with multi-directional forces.

Long Service Life: The bearing is usually filled with long-lasting lubricating grease, eliminating the need for frequent relubrication under normal operating conditions, reducing maintenance workload.

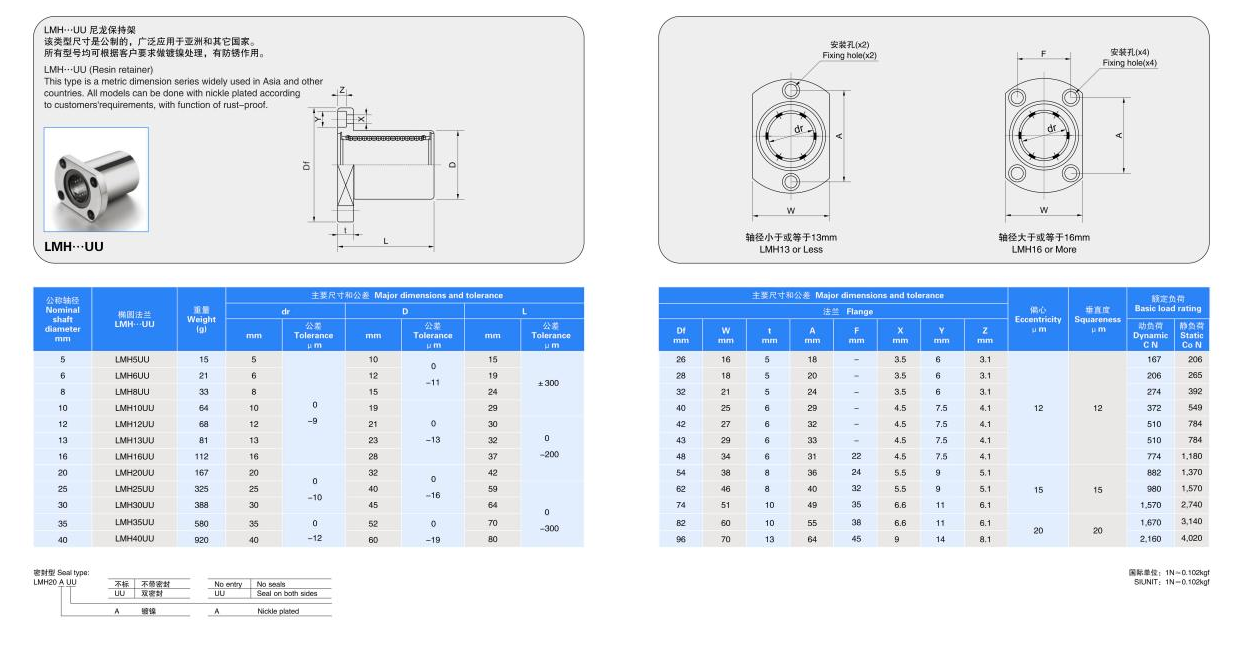

Product Specifications