Product Information

I. Application Areas

1. Automation and Precision Machinery: 3D printing, desktop CNC machines, small linear modules, supporting light loads at high speeds and micron-level repeatable positioning.

2. Electronics and Semiconductors: Wafer transfer, precision alignment platforms, requiring low friction and clean operation.

3. Medical and Life Sciences: Imaging equipment slides, analytical instrument stages, emphasizing low vibration and adjustable preload.

4. Food and Packaging: Small-scale filling, labeling, and sorting, suitable for clean environments and limited installation space.

5. Instrumentation and Metrology: Coordinate measuring machines, optical platforms, requiring high linearity and stability.

6. Robotics and Collaborative Equipment: SCARA/Delta joints, end effectors, pursuing compactness and rapid assembly.

7. Office and Commercial Equipment: ATMs, scanners, prioritizing low noise and maintenance-free operation.

II. Advantages

1. Adjustable Clearance and Micro-Preload: Clearance is controlled through radial contraction, improving rigidity and repeatable positioning accuracy (typically ±10 μm), suitable for on-site fine-tuning.

2. Low Friction and High Sensitivity: Low rolling friction coefficient, smooth start and stop, fast response, beneficial for light loads at high speeds and micron-level resolution.

3. Space-Friendly and Rapid Assembly: Compact structure and easy installation, often used with cylindrical optical shafts, shortening the debugging cycle.

4. Installation Tolerance and Alignment Forgiveness: Allows for small installation deviations, reducing the stringent requirements for shaft coaxiality.

5. Convenient Maintenance and Cost-Effectiveness: Standardized interfaces and strong interchangeability; some models are sealed, reducing maintenance and spare parts costs.

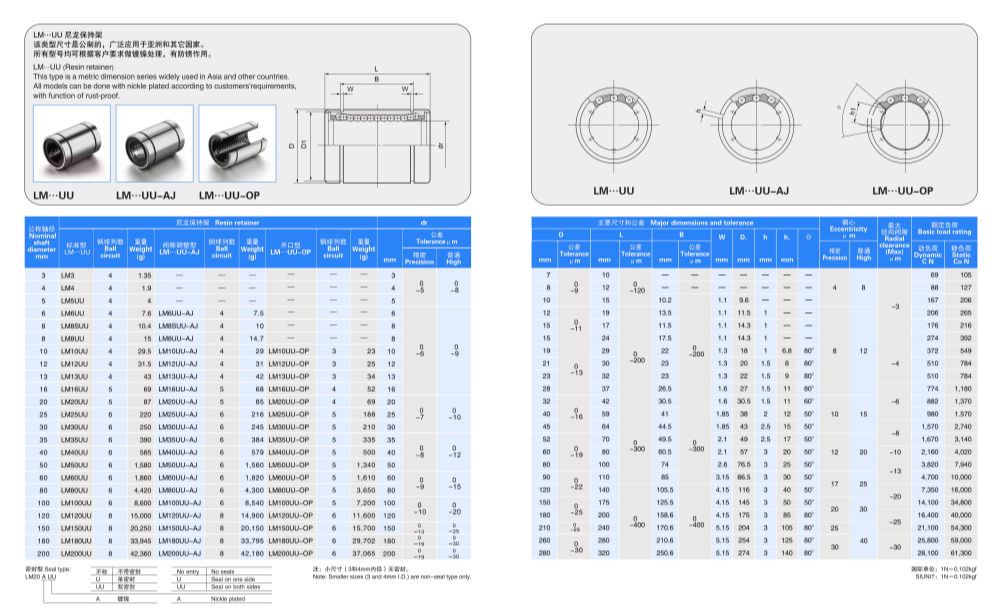

Product Specification