Product Information

I. Application Fields

Extended linear bearings (compared to standard linear bearings, their body length is longer, usually 1.5-3 times that of the standard type) possess the characteristics of "longer guiding section, stronger resistance to eccentric loads, and higher motion stability."

Spindle feed systems: The longitudinal/transverse feed mechanisms of the worktables of lathes, milling machines, and grinding machines. Extended bearings ensure the linear motion accuracy (straightness ≤ 0.05 mm/m) of the tool or workpiece through a longer guiding section, reducing vibrations caused by high-speed cutting.

Industrial robot arms: The telescopic arms and lifting shafts of multi-joint robots. Extended bearings can withstand the gravitational eccentric load and motion inertia force at the cantilever end, improving repetitive positioning accuracy (usually up to ±0.01 mm).

Coordinate measuring machines: The guiding mechanisms of the X/Y/Z axes. The high linearity and low friction characteristics (dynamic friction coefficient ≤ 0.002) of extended bearings ensure the trajectory accuracy of the measuring probe, reducing measurement errors.

Laser interferometer calibration equipment: The guiding of the moving platform. The extended structure avoids optical path deviation caused by equipment vibration, ensuring the reliability of calibration data.

Heavy-duty worktables/lifts: Such as large worktables for mold processing. Extended bearings distribute the load through a longer contact length (can withstand several tons of radial force), reducing local wear on the shaft and bearing.

Port/logistics automation: The lifting guide rails of stacker cranes. Extended bearings are suitable for high-frequency, heavy-load reciprocating motion, improving equipment life (usually more than 100,000 hours).

II. Advantages of Use

Reduced speed fluctuations and impact effects: In high-speed reciprocating motion (such as the sorting mechanism of packaging machinery), the extended structure disperses the inertial impact at the moment of starting and stopping through a longer guiding section, reducing the "chatter" of moving parts, especially suitable for scenarios requiring high stability (such as sample transfer in medical equipment). Improved Overturning Moment Resistance: When moving parts are subjected to eccentric loads (such as the load at the end of a cantilevered robotic arm), the longer guide section of the bearing distributes the moment through more support points, suppressing local stress concentration between the bearing and the shaft, and reducing the risk of jamming or wear caused by eccentric loading. Compared to standard types, its overturning resistance can be increased by 30%-60%.

Extended Service Life: The increased contact length reduces the load per unit area, decreasing the wear rate of the rolling elements or sliding surfaces.

Improved Environmental Adaptability: For working conditions with dust and slight corrosion (such as outdoor new energy equipment), the longer structure allows for increased space for sealing components (such as adding dust seals at both ends), improving the protection level (up to IP65); in clean environments (such as semiconductor workshops), the longer self-lubricating plastic bearings can reduce lubricant evaporation, meeting dust-free requirements.

Reduced Need for Auxiliary Guiding Components: A single long bearing can provide sufficient guiding accuracy, eliminating the need for additional support structures, simplifying equipment layout, and reducing overall weight and cost. For example, the fine-tuning mechanism of small testing instruments can replace the traditional "dual standard bearings + spacer" combination with a single long bearing.

Reduced Maintenance Frequency: Due to uniform wear and strong resistance to interference, the maintenance cycle of long bearings is typically 2-3 times longer than standard types, making them particularly suitable for scenarios where frequent downtime for maintenance is difficult.

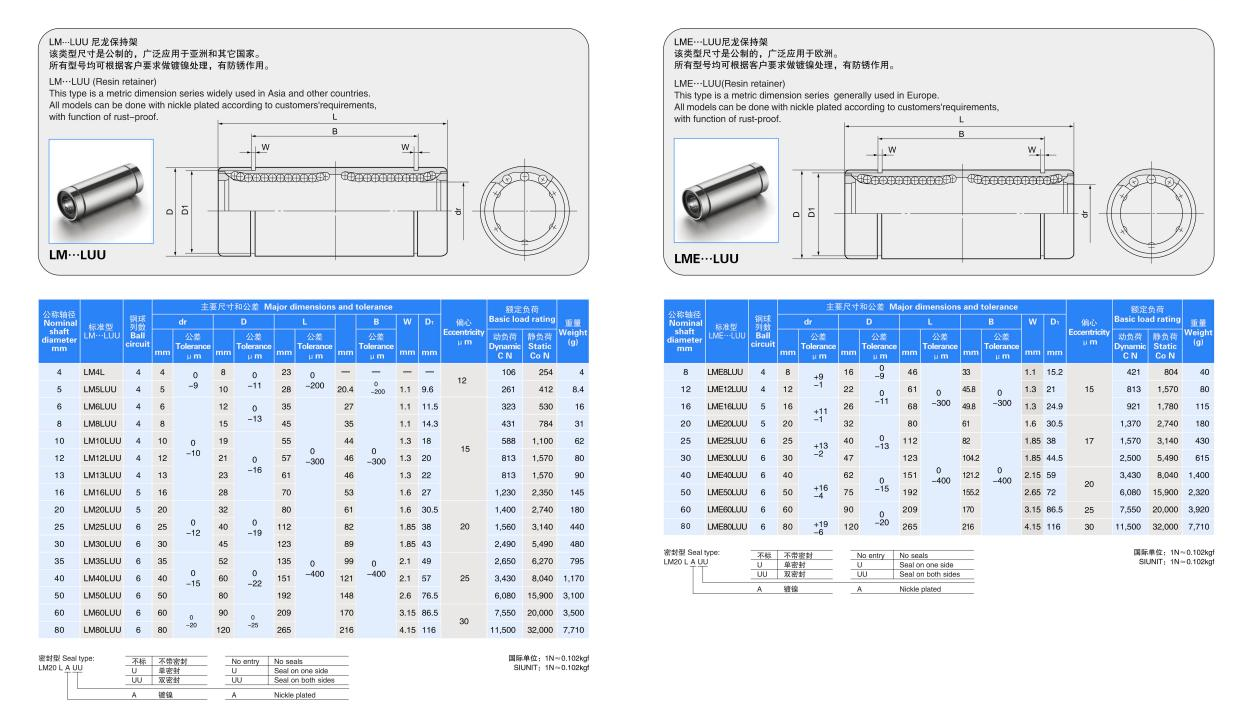

Product Specifications