Product Information

I. Application Areas

1. Automated Production Lines and Conveying Equipment: Tensioning shaft guidance for belt conveyors, slide rail support for small material lifting machines, and push rod motion guidance for automatic sorting machines.

2. Packaging and Food Machinery: Film traction shaft for pillow packaging machines, bottle positioning slide table for filling machines, and baking tray pushing mechanism for biscuit production lines.

3. Woodworking and Textile Machinery: Z-axis auxiliary guidance for woodworking engraving machines, needle bar up-and-down motion support for sewing machines, and yarn tension adjustment shaft for winding machines.

4. Agricultural and Small Construction Machinery: Seed dispenser adjustment slide rod for seeders, cutting blade guide shaft for small harvesters, and sprinkler translation mechanism for irrigation equipment.

Fitness and Office Equipment: Treadmill belt tensioning shaft support, resistance adjustment rod guidance for exercise bikes, and column sliding mechanism for height-adjustable office desks.

II. Advantages

1. Balanced Guidance Stability and Anti-Eccentric Load Capacity: The increased contact length between the elongated body (e.g., a bearing with an inner diameter of 16mm and a length of 50-70mm) and the guide shaft results in radial runout controlled within ±0.02mm, superior to shorter bearings; the symmetrical fixing with a circular flange improves anti-eccentric load performance by 30% compared to flangeless bearings, suitable for medium to long stroke (≥200mm) reciprocating motion.

2. High Installation Flexibility and Adaptability to Diverse Structures: The circular flange has no directional limitations and can be fixed at any angle, especially suitable for curved mounting surfaces (such as cylindrical frames and curved housings), eliminating the need for additional machining of positioning grooves.

3. Convenient Maintenance and Controllable Costs: Standardized dimensions (conforming to ISO and DIN standards), strong compatibility with guide shafts, locking nuts, and other accessories; no need to modify the equipment structure for replacement, resulting in 25%-30% lower maintenance costs compared to custom bearings.

4. Smooth Operation for Multiple Scenarios: The elongated body has a low sliding friction coefficient (≤0.002), eliminating "creeping" phenomena in low-speed (≤0.8m/s) reciprocating motion, suitable for packaging machines, office equipment, and other applications requiring high operational smoothness.

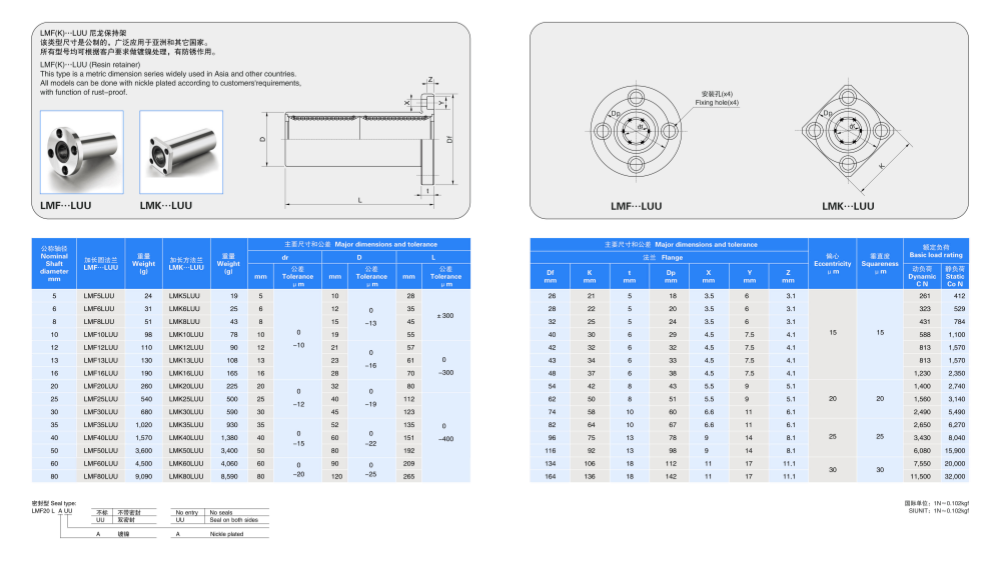

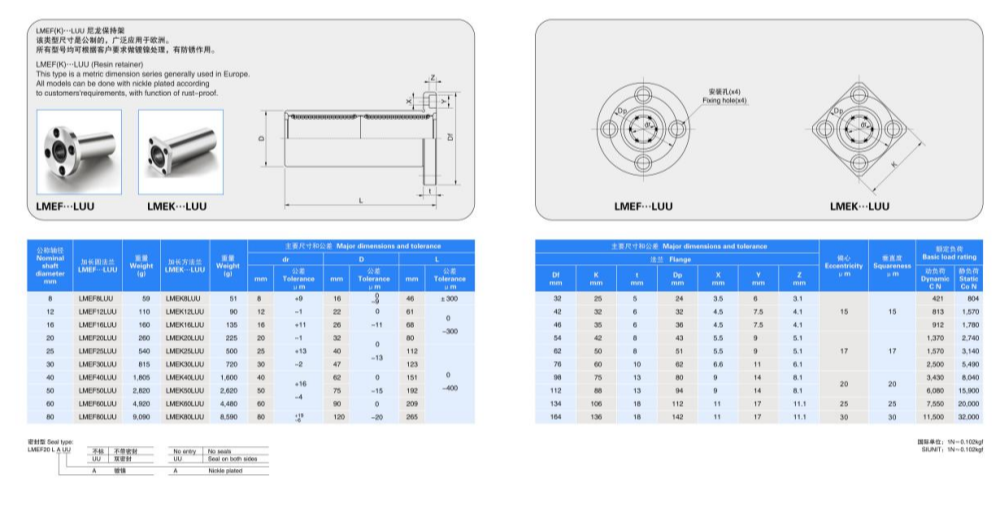

Product Specifications