Product Information

I. Application Areas

1. Precision Instruments and Measuring Equipment: Translation mechanism of the stage of optical microscopes, optical path adjustment axis of laser interferometers, lens movement guide rails of image measuring instruments.

2. Medical and Laboratory Equipment: Sample pushing slide of blood analyzers, liquid dispensing mechanism of infusion pumps, heat cover lifting guide of PCR machines.

3. Automated Assembly and Conveying Equipment: Sorting slide for small parts (such as electronic connectors), bit positioning axis of screw machines, alignment mechanism of lithium battery electrode stacking machines.

Packaging and Printing Machinery: Label head traverse mechanism of labeling machines, workbench lifting of small hot stamping machines, plate roller fine adjustment axis of flexographic printing machines.

II. Advantages

1. Extended Body Suppresses Deformation: The bearing body length is increased by 50%-80% compared to the standard type (e.g., a bearing with an inner diameter of 10mm can have a length of 40-60mm). The longer contact length with the optical axis effectively reduces the bending deflection of slender shafts during medium to long strokes (50-300mm). Radial runout can be controlled within ±0.01mm, ensuring the linearity of feeding, transfer, and other movements (error ≤0.05mm/m), superior to short bearings.

2. Square Flange Improves Fit: The mounting surface of the square flange is flat, and the bolt holes are mostly distributed at the four corners (e.g., 4-M5 threaded holes). The contact area with the equipment frame is more than 30% larger than that of a circular flange, effectively preventing "loosening and shifting" under vibration conditions, especially suitable for high-frequency reciprocating motion (such as the nozzle movement of automatic dispensing machines).

Flexible Installation Direction: The square flange can be fixed horizontally, vertically, or diagonally according to the equipment structure requirements, without the need for strict matching of the mounting surface angle, reducing the design and assembly difficulty of non-standard equipment.

3. High Compatibility with Standardized Dimensions: Inner diameter (6mm-50mm), flange size, etc., comply with international standards (such as JIS, ISO), and have strong compatibility with optical shafts, sliders, and other accessories. No modification of the equipment structure is required during later maintenance, and the replacement cost is 30%-50% lower than that of customized bearings.

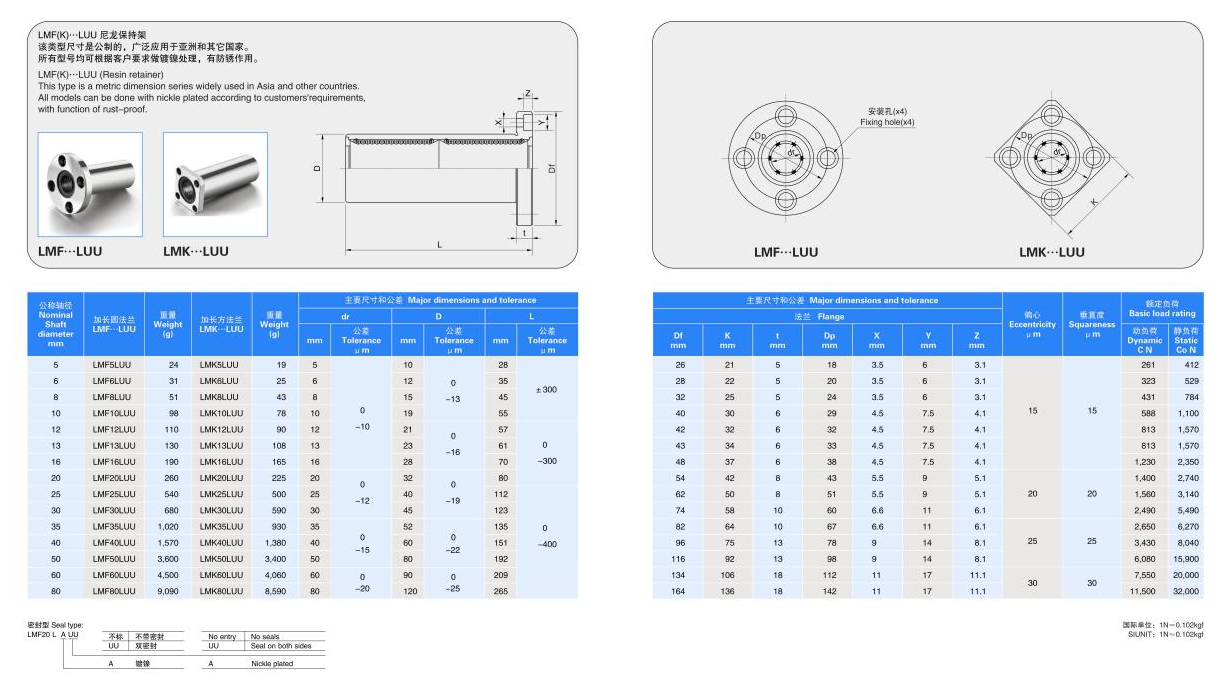

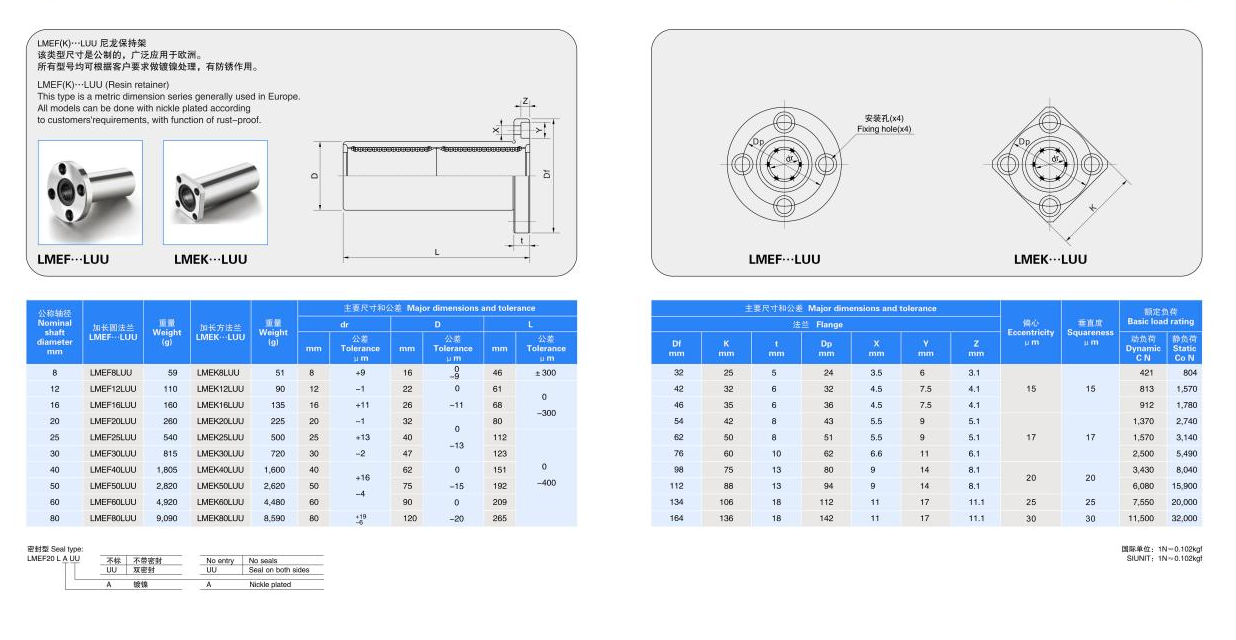

Product Specifications