Product Information

I. Application Areas

Automated Production Lines and Robots: Linear guidance for sliders or pushers, robotic arm extension and retraction, achieving repetitive positioning and stable motion.

Precision Machine Tools and CNC: Worktable feeding, tool magazine changing, meeting requirements for micro-feed and low noise.

Medical and Imaging Equipment: CT/MRI bed movement, surgical microscope adjustment, requiring cleanliness, low noise, and stability.

Electronics and Semiconductors: Wafer transfer or positioning, pick-and-place machine worktables, pursuing nanometer-level displacement and high cleanliness.

Food Packaging and Pharmaceuticals: Conveying, sorting, labeling, supporting frequent start-stop and hygiene requirements; some brands are washable.

Textile, Printing, and Logistics: High-speed or heavy-load applications, providing compact installation and reliable guidance.

II. Advantages

Convenient Installation and Stable Axial Positioning: The flanged edge is directly bolted, simplifying alignment, shortening assembly time, and reducing assembly skill requirements. Compact Structure Saves Space: The outer ring and flange are integrated, without additional mounting bases, suitable for confined spaces and miniaturized equipment. High Guidance Accuracy and Strong Anti-Tilting: With guiding or leading end design, precise fit with the shaft improves linearity and repetitive positioning accuracy, suppressing wobbling. Low Friction and Low Noise: Rolling element circulation, low friction coefficient, smooth operation, low noise, and fast response. Balanced Load Capacity and Impact Resistance: Dual-circulation or extended structure options available, the flange increases the force-bearing surface, adapting to various working conditions from light load and high speed to heavy load and low speed. Easy Maintenance and Long Service Life: Standard parts are easy to replace, lubrication and sealing are mature, reducing downtime and maintenance costs.

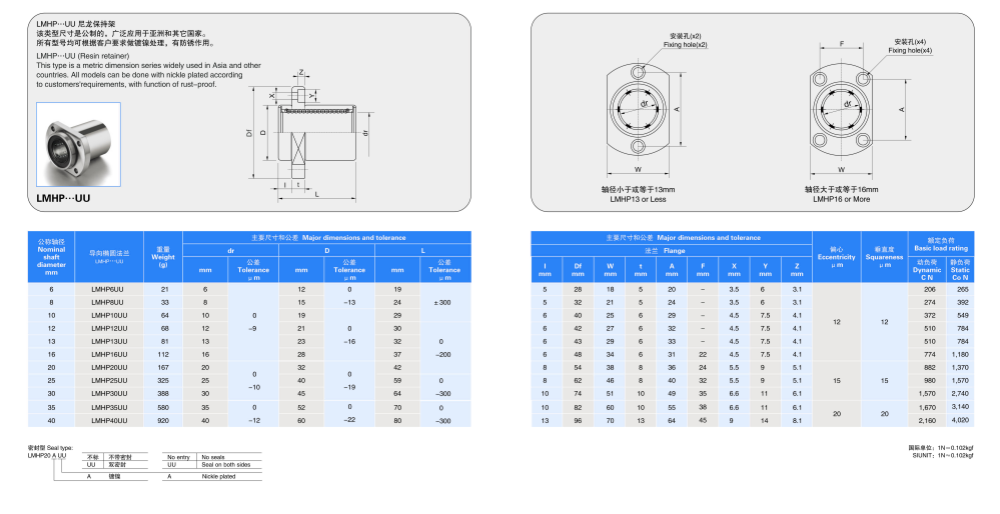

Product Specifications