Product Information

I. Application Areas

1. CNC Machine Tools and Robots: Square flanges, with evenly distributed bolts (e.g., 4-hole or 6-hole configurations), offer 30%-50% higher resistance to overturning moments compared to round flanges. They are suitable for applications requiring high rigidity and dynamic response, such as the tool holder feed systems of CNC machine tools and SCARA robot joints.

2. Wafer Transfer and Inspection: Flange bearings with guide grooves can absorb installation deviations (e.g., ±0.1mm coaxiality error), ensuring smooth wafer transfer without jamming, meeting the low particle release requirements of semiconductor cleanrooms.

3. Imaging Equipment: The slip ring guide rails of CT scanners use corrosion-resistant stainless steel flange bearings, combined with double-lip fluororubber seals (2RS type), allowing for stable operation in environments ranging from -20℃ to 80℃, and meeting medical-grade cleanliness standards.

4. Chemical Corrosion Environments: PTFE guide flange bearings can withstand strong acids and bases (such as sulfuric acid and sodium hydroxide), and are used for guiding the stirring shafts of reactors in chemical equipment, extending their lifespan by more than twice compared to stainless steel bearings.

II. Advantages

1. High Rigidity and Overturning Resistance: The larger bolt distribution radius of square flanges (e.g., the bolt spacing of a 4-hole flange is 40% greater than that of a round flange) increases the overturning moment resistance by more than 50%, making them suitable for long-span or cantilever load applications.

Enhanced Guidance with Guide Grooves: The integrated V-shaped or dovetail groove structure constrains radial oscillation. For example, in robot end effectors, guide flange bearings can control oscillation errors within ±10μm.

2. Fast Installation and High-Precision Alignment: The guide bevels (angles of 10°~30°) and positioning pin holes on the flange edge eliminate the need for repeated adjustments during installation, allowing for positioning within 30 seconds, which is 3 times more efficient than traditional round flanges.

Tolerant Installation: The clearance fit (H7/g6) between the bearing inner ring and the shaft allows for ±0.05mm installation deviation, reducing the requirements for the parallelism of the mounting surface (planarity ≤0.02mm/m is sufficient). 3. Standardized interface: Fully compatible with square optical shafts (SFJ series) from mainstream brands such as Misumi and IAI, with spare parts costs 40% lower than imported brands.

4. Tool-free maintenance: Some models support online replacement (such as those with quick-release flanges), eliminating the need to disassemble the entire module, reducing maintenance time to 1/5 of traditional solutions.

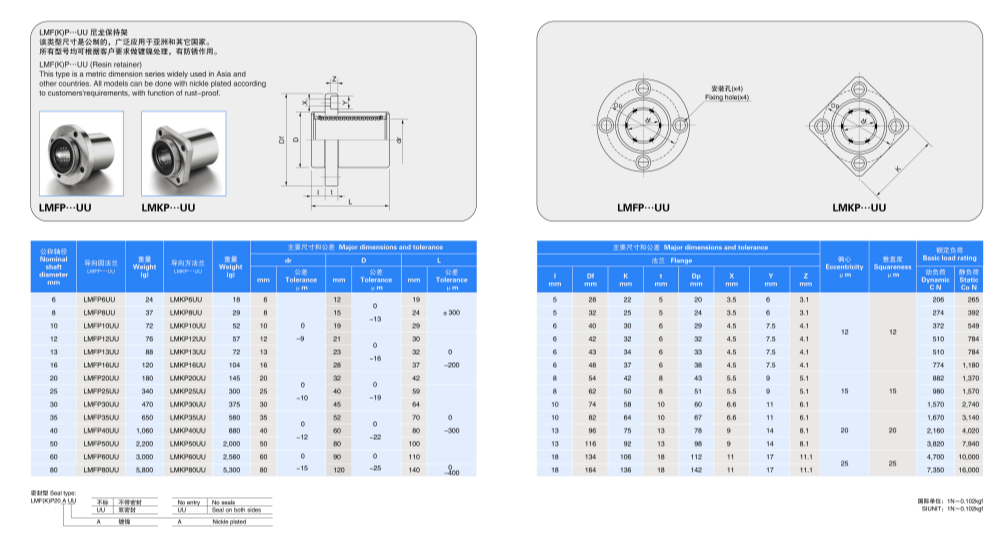

Product Specifications