Product Information

I. Application Areas

Chemical Industry: In chemical production, round flanges are used to connect various chemical equipment and pipelines, such as reactors, evaporators, and storage tanks. Their corrosion resistance allows them to withstand highly corrosive materials and prevent leakage accidents.

Construction and Environmental Engineering: In building ventilation and fire protection systems, round flanges can withstand humid, acidic, and alkaline environments, extending equipment lifespan. In sewage treatment facilities, their corrosion resistance effectively combats sewage corrosion, ensuring stable system operation.

Power Industry: They can be used to connect equipment such as boilers and heat exchangers, maintaining stable performance in high-temperature and high-pressure environments, ensuring the safety and efficiency of power generation.

Shipbuilding Industry: Various piping systems on ships, such as fuel pipelines, seawater pipelines, and ventilation pipelines, require the use of round flanges for connection and sealing to ensure the reliable operation of the piping system during navigation.

II. Advantages and Features

High Pressure Resistance: The structural design gives it strong pressure resistance, enabling it to adapt to the demands of high-pressure working environments. It performs excellently in pipeline connections involving high temperatures, high pressures, and corrosive media, ensuring the long-term stable operation of the pipeline system.

Easy Installation and Disassembly: Round flanges are tightly connected by bolts and other fasteners, forming a secure mechanical connection. This connection method is easy to install and disassemble, suitable for equipment and pipelines that require frequent cleaning, inspection, or replacement. This facilitates maintenance by technicians, reducing downtime and maintenance costs.

High Degree of Standardization: Adopting a standardized design, it conforms to standards and specifications in multiple countries and regions, allowing it to be used with equipment and pipelines from various brands, improving equipment interchangeability and versatility.

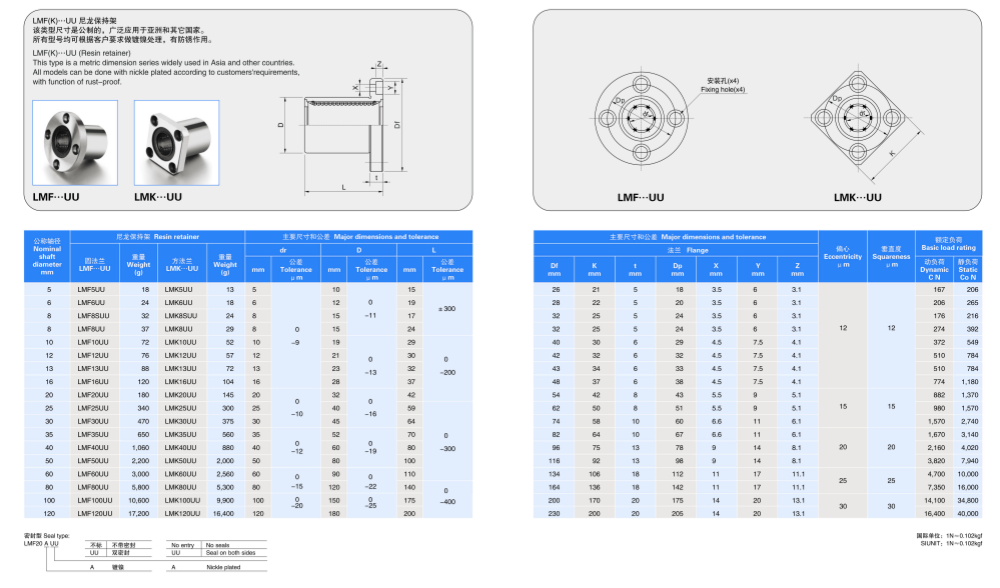

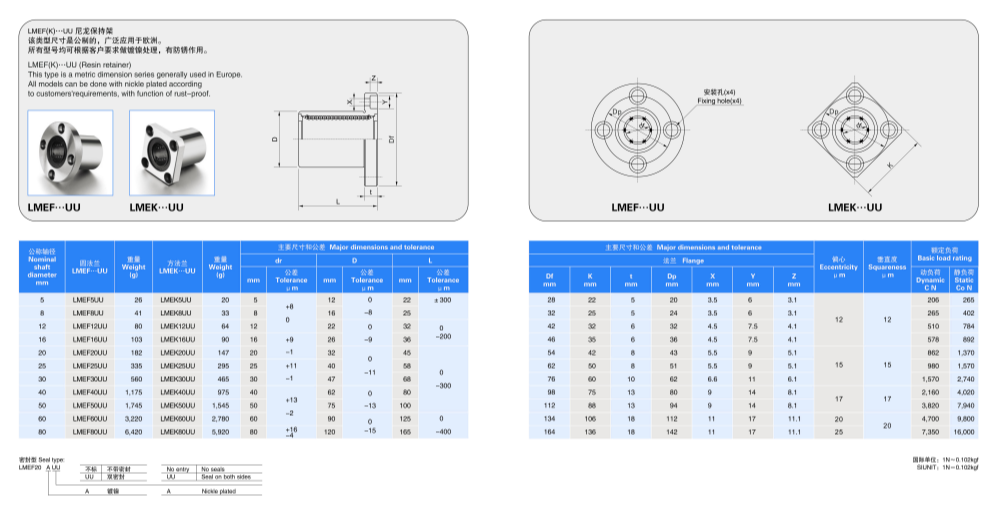

Product Specifications