Product Information

The center-flanged square linear bearing (whose flange is square and located in the middle of the bearing) is suitable for applications requiring specific installation stability, balanced force distribution, and spatial layout due to the stable mounting characteristics of the square flange, the structural advantages of center positioning, and the versatility of standard components.

I. Application Areas

Small and medium-sized automation equipment: such as linear guiding components for precision feeding mechanisms, transfer platforms, and robotic arms.

Small machine tool feeding systems: such as the worktable movement guidance of desktop milling machines and engraving machines. The square flange facilitates symmetrical bolt fixing, and combined with center positioning, it can improve the linearity of the feeding motion, meeting the accuracy requirements of micro-cutting.

Tool magazines and tool changing mechanisms: In the linear motion of rapid tool switching, the center-flanged square bearing provides stable support, reduces vibration during high-speed movement, and ensures the accuracy of the tool change position.

Laboratory precision platforms: such as the linear adjustment mechanisms of microscope stages and sample shaking devices, which require low friction and high stability motion. The center-flanged square bearing can meet the requirements for smooth operation and repeatable positioning.

Semiconductor packaging equipment: In processes such as chip handling and wire bonding, the equipment requires extremely high motion accuracy (micron level) and anti-interference capabilities. The symmetrical structure of the center-flanged square bearing can reduce the impact of installation stress on the bearing, ensuring the stability of chip transfer.

II. Advantages

Superior fit: The square flange has a larger contact area with the mounting surface, and the right-angle design of the corners facilitates symmetrical bolt fixing (usually 4 mounting holes), which can effectively disperse installation stress and reduce loosening caused by vibration or eccentric loads.

Symmetrical force distribution with center positioning: The flange is located in the middle of the bearing, making the bearing closer to the center of gravity when subjected to axial force, resulting in stronger resistance to overturning moments (moments rotating around the axis), especially suitable for cantilevered installations or working conditions with lateral forces (such as robotic arm extension and retraction, and worktable pushing and pulling). Design Advantages: The centrally located flange design avoids limiting the travel range of moving parts due to end flanges, and also reduces interference with other equipment components (such as guide rails, sensors, and pipelines). This makes it suitable for applications with limited space and requiring symmetrical layouts (such as small automation equipment and the interiors of precision instruments).

Symmetrical Structure Reduces Errors: The central square flange ensures a more centered fit between the bearing and the shaft. During installation, it is less likely that flange misalignment will cause deviations in the coaxiality of the shaft and bearing, thus guaranteeing the linearity of the linear motion (typically within 0.1 mm/m).

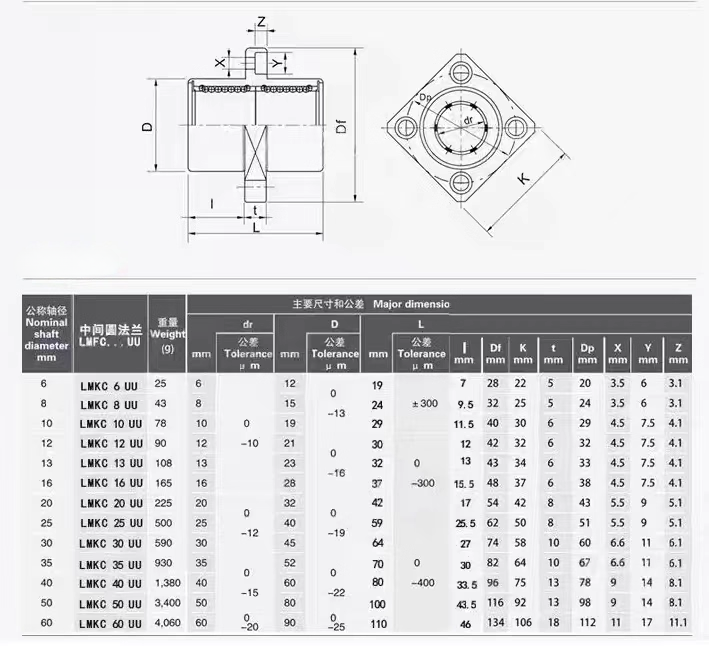

Product Specifications