Product Information

I. Application Areas

1. Semiconductor and 3C Automation: Wafer transfer, pick-and-place, small-scale transfer, alignment

2. Food and Packaging Machinery: Feeding, paper handling, sealing head movement, packaging modules

3. Medical and Imaging Equipment: Imaging bed translation, small-scale surgery, rehabilitation robotic arms

4. New Energy Equipment: Battery electrode sheet slitting, stacking, labeling auxiliary axis: long-stroke guidance, stable, anti-eccentric load, reduces vibration, improves consistency

5. Automation Assembly and Sorting: Multi-axis slide table, palletizing, transfer auxiliary axis: centered fixing, strong modularity, shortened design and assembly cycle

6. Precision Machine Tools and Tooling Machines: Small, precision machine tool slide tables, tool magazine movement

7. Inspection and Measurement Instruments: Optical platform, three-coordinate auxiliary axis: low friction, good repeatability

II. Advantages

1. Enhanced Anti-Eccentric Load Capacity: The centered fixing method of the intermediate flange makes the load distribution more symmetrical. Combined with the multi-point support of the extended body, the anti-eccentric load performance is improved by more than 35% compared to bearings installed at the ends, reducing jamming or uneven wear caused by unilateral force and extending service life (up to 800,000-1.2 million cycles under normal working conditions).

2. Square Flange Improves Fixing Reliability: The square flange (usually square or rectangular) has a larger mounting surface, and the bolt holes are symmetrically distributed (such as 4 corner holes), resulting in a better fit with the equipment frame. This effectively avoids "loosening and shifting" of circular flanges under vibration conditions, especially suitable for high-frequency reciprocating motion scenarios.

3. Square Edge Design Adapts to Compact Environments: Some models of square flanges have chamfered edges (removing redundant corners), which further reduces the radial size. In multi-axis parallel (such as XY slide tables) and high-density layout automation workstations, it can avoid interference with adjacent cylinders, motors, sensors, and other components, improving space utilization.

4. Flexible Installation Direction: The symmetry of the square flange allows for horizontal, vertical, or diagonal fixing, without the need for strict matching of the mounting surface angle, especially suitable for modular design of non-standard equipment, reducing assembly difficulty.

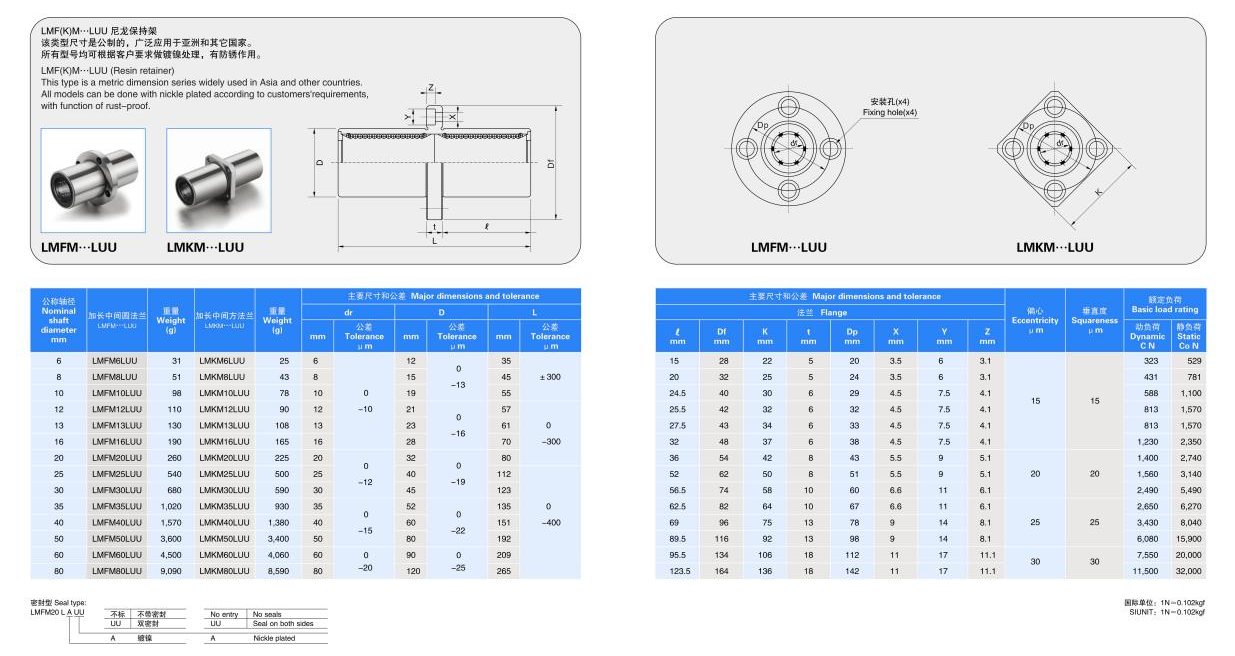

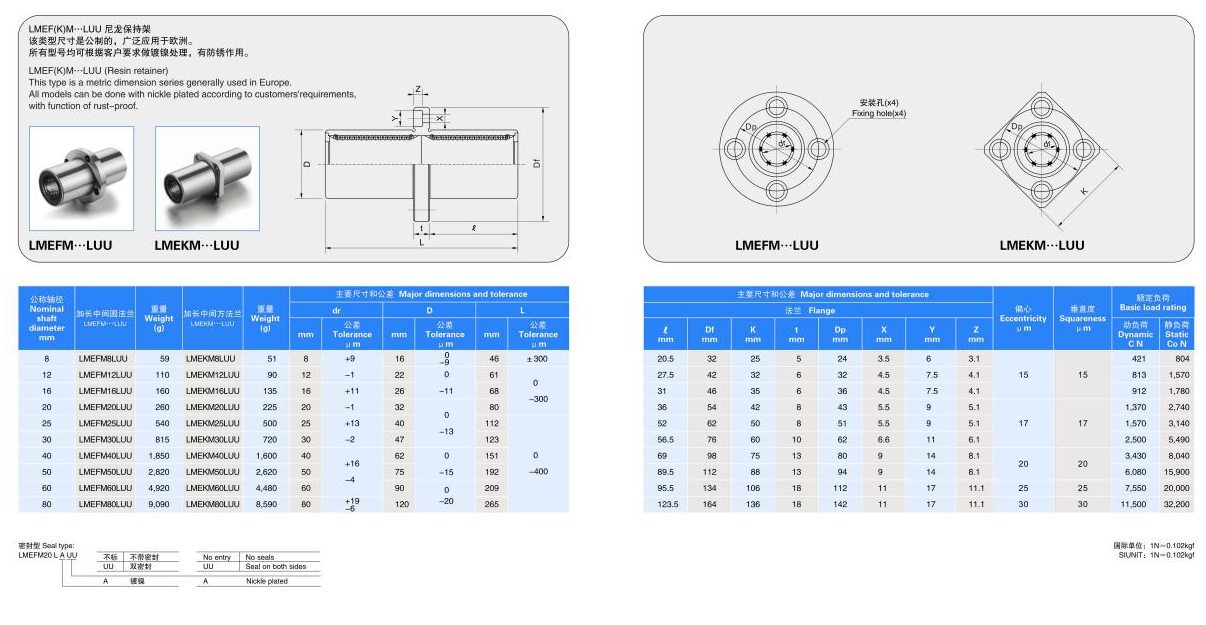

Product Specifications