Product Information

I. Application Areas

Automated Small-Scale Handling and Assembly Equipment: In small robotic arms and material transfer slides (such as mobile phone component handling in the 3C industry), the extended body ensures linearity of long-stroke motion (80-200mm), and the centrally located flanged edge allows for secure mounting to the middle of the equipment frame. The beveled edge design reduces redundant space at the flange edge, preventing interference with adjacent cylinders, sensors, and other components, making it suitable for high-density automated workstations.

Precision Instruments and Testing Equipment: Such as micro-adjustment slides for optical inspection platforms and auxiliary guide shafts for coordinate measuring machines, the extended bearing body reduces the deflection of slender optical shafts and improves stability during micro-feed movements; the thin structure of the centrally located flanged edge (thickness usually ≤5mm) is suitable for installation in confined spaces within equipment, and its low friction characteristics meet the high-precision positioning requirements during testing (repeatability within ±0.01mm).

Linear Motion Components for Medical Equipment: Such as the injection slider of infusion pumps and the telescopic arms of small rehabilitation devices, the extended body provides stable guidance, and the compact design of the centrally located flanged edge suits the "miniaturization" needs of medical equipment. Some models with sealing covers can meet clean environment requirements (preventing the intrusion of liquids and dust).

II. Advantages

Extended Body Enhances Guiding Accuracy: The bearing body length is 30%-50% longer than the standard type (e.g., a bearing with an inner diameter of 16mm can have a length of 60-80mm). The longer contact length with the optical shaft effectively suppresses deflection and vibration, especially in medium-to-long stroke (80-300mm) movements, controlling radial runout within ±0.02mm and ensuring the smoothness of feeding and transfer operations.

Central Mounting Saves Axial Space: The flange is located in the middle of the bearing, eliminating the need for additional axial fixing space required by end flanges. In scenarios with limited travel, such as lifting mechanisms and telescopic arms, it can reduce the overall size of the equipment, saving 15%-25% of axial length compared to end-mounting solutions. Fast positioning and fixing: The central flange comes with standardized mounting holes (compatible with M3-M6 bolts), eliminating the need for complex positioning fixtures. It can be directly fixed by aligning it with the mounting surface of the equipment frame. The installation time per unit is reduced by 60% compared to non-standard bearings, making it especially suitable for mass assembly in automated production lines or for retrofitting existing equipment.

Superior cost-effectiveness compared to linear guides: In light to medium load (≤300N) and non-ultra-high precision (repeatability within ±0.01mm) applications, the cost is only 1/3 to 1/4 of comparable linear guides. This significantly reduces overall procurement costs, especially in multi-axis parallel equipment.

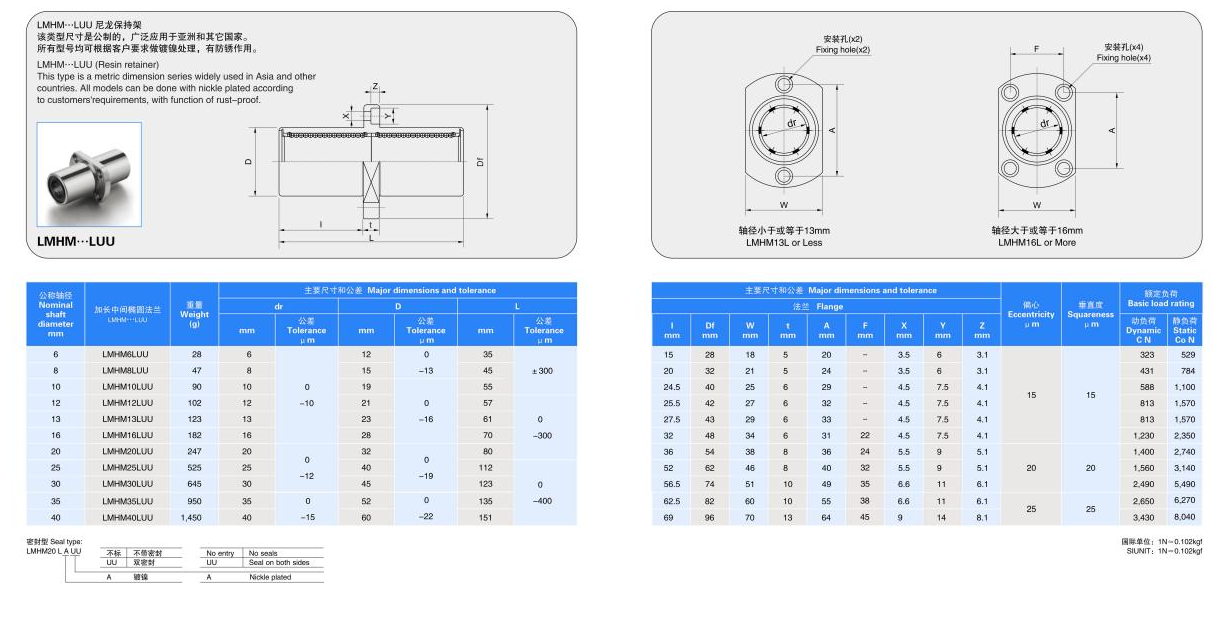

Product Specifications