Product Information

I. Application Areas

1. Automated Conveying and Transfer Equipment: In long-stroke material conveying lines and lifting and transfer mechanisms, the extended bearing body provides a longer guiding section, reducing the impact of shaft deflection on motion accuracy. The symmetrical mounting structure with a central circular flange provides stable support for belt/chain-driven slides, suitable for continuous feeding requirements in the food and electronics industries.

2. Precision Machine Tools and Processing Equipment: Suitable for the worktable feed guidance of small and medium-sized milling machines and grinding machines, or the Z-axis vertical motion mechanism of engraving machines. The extended body reduces vibration during high-speed motion, and the central flange fixing method evenly distributes the load, ensuring positioning stability during cutting or engraving (repeatability within ±0.02mm).

3. Medical and Laboratory Equipment: Such as the injection mechanism of infusion pumps and the sample rack transfer track of biochemical analyzers, the extended body ensures the straightness of the slender shaft, and the compact installation of the central flange is suitable for modular layouts inside the equipment. Some models with seals can meet the requirements of clean environments (such as dustproof and splash-proof).

4. Heavy-Duty Non-Standard Machinery Auxiliary Guidance: On the auxiliary guide shafts of small presses and stamping equipment, compared with ordinary linear bearings, the extended body can share the radial load of the main force-bearing shaft, and the symmetrical fixing of the central circular flange reduces jamming caused by eccentric loads, extending equipment life.

II. Advantages

1. Higher Load Capacity and Resistance to Eccentric Loads: The extended body increases the ball contact length, distributing the load evenly, resulting in more stable operation and longer life under medium load conditions.

2. Convenient Installation and Centered Structure: The central flange is fixed in the center, reducing cantilever/span, enabling quick positioning, and lowering assembly and maintenance costs.

3. Smooth Motion and Low Friction: Ball circulation rolling results in a low friction coefficient.

4. Dustproof and Protective: Standard seals block dust/debris, improving lifespan in harsh environments.

5. Standardization and Interchangeability: Standard inner diameter matches the shaft, simplifying design/replacement and shortening delivery time.

6. Temperature Adaptability: Conventional -20℃ to +80℃, suitable for most industrial environments.

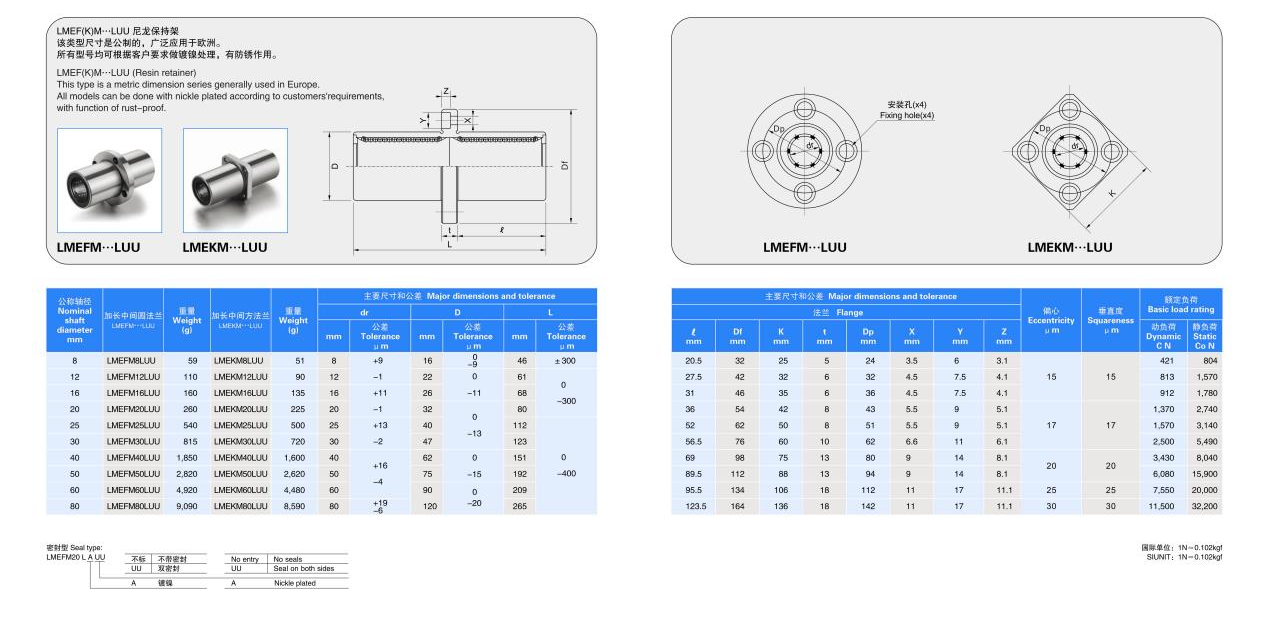

Product Specifications