Product Information

I. Application Areas

1. automation and industrial robotics: scara/delta joints, transfer and sorting, requiring high rigidity and rapid assembly.

2. precision machine tools and woodworking machinery: x/y slides, tool holder feeding, pursuing high precision and rigidity.

3. electronics and semiconductor equipment: wafer transfer, dispensing/placement, emphasizing cleanliness, low friction, and repeatable positioning.

4. medical and life sciences: imaging equipment platforms, analytical instruments, emphasizing low vibration and stable operation.

5. packaging and food machinery: labeling, filling, conveying, requiring compact structure and easy maintenance.

6. printing and textile machinery: paper/fabric feeding mechanisms, requiring high speed and low friction.

ii. advantages

1. higher rigidity and anti-tilting: the guide groove enhances radial and tilting rigidity, suppressing deflection, suitable for heavy loads and high dynamics.

2. convenient installation and space saving: the intermediate flange can be directly locked, used with cylindrical shafts, shortening the debugging cycle.

3. low friction and high sensitivity: low rolling friction coefficient, smooth start and stop, beneficial for high speed and micron-level resolution.

4. strong standardization and interchangeability: universal interface, easily available spare parts, low maintenance costs.

5. compact structure and cost-effective: compared with square guide rail systems, it saves space and cost, suitable for small and medium-sized equipment.

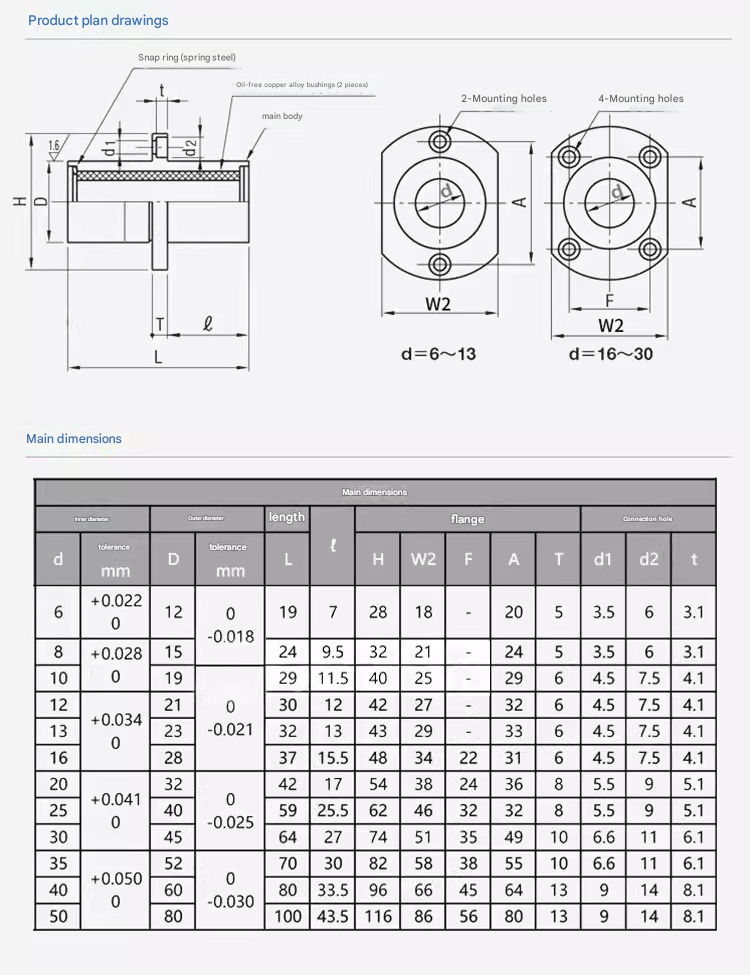

Product Specifications