Product Information

A linear guide rail and slider is a common mechanical device consisting of a guide rail and a slider, which work together to achieve smooth movement of an object. The following is a detailed introduction:

- Core Structure: The guide rail is usually made of high-strength alloy steel, precision ground and heat-treated, and features precisely machined raceways. The slider integrates a ball bearing system, including balls, a cage, and a return mechanism. The balls contact the raceways of the guide rail, creating rolling friction. In addition, linear guide rails are often equipped with sealing devices and lubrication systems to extend their service life.

- Working Principle: Based on the concept of "replacing sliding friction with rolling friction," when the slider carries an external load, the load is transmitted through the slider to the internal balls, and then evenly distributed to the raceways of the guide rail. The balls roll in the raceways inside the slider, and when they reach the end of the slider, they enter the return channel through the return mechanism, forming a closed loop. At the same time, pre-tension adjustment eliminates the gap between the balls and the raceways, improving the system's rigidity and positioning accuracy.

- Material Selection: Common materials for guide rails and sliders include metal materials such as aluminum alloys and steel, which have high strength and rigidity and are suitable for heavy-load applications; engineering plastics such as polyamide and polytetrafluoroethylene, which have chemical stability, wear resistance, and self-lubricating properties, and are suitable for light-load, high-speed motion applications; and composite materials, which combine metals and engineering plastics to utilize the advantages of both.

- Main Types: These include ball guide rail sliders, roller guide rail sliders, linear guide rail sliders, and curved guide rail sliders. Ball guide rail sliders offer high precision and speed; roller guide rail sliders have strong load capacity and good wear resistance; linear guide rail sliders have a simple structure and are easy to install; and curved guide rail sliders are suitable for curved motion equipment.

- Application Fields: Widely used in machine tools and automated production lines, transportation and logistics, linear motion control, stage and aerospace, automotive and transportation, and other fields. For example, in machine tools, they are used to achieve accurate positioning and processing of workpieces; in the logistics industry, they are used for conveying goods on conveyor belts; and in the aerospace field, they are used for moving spacecraft components.

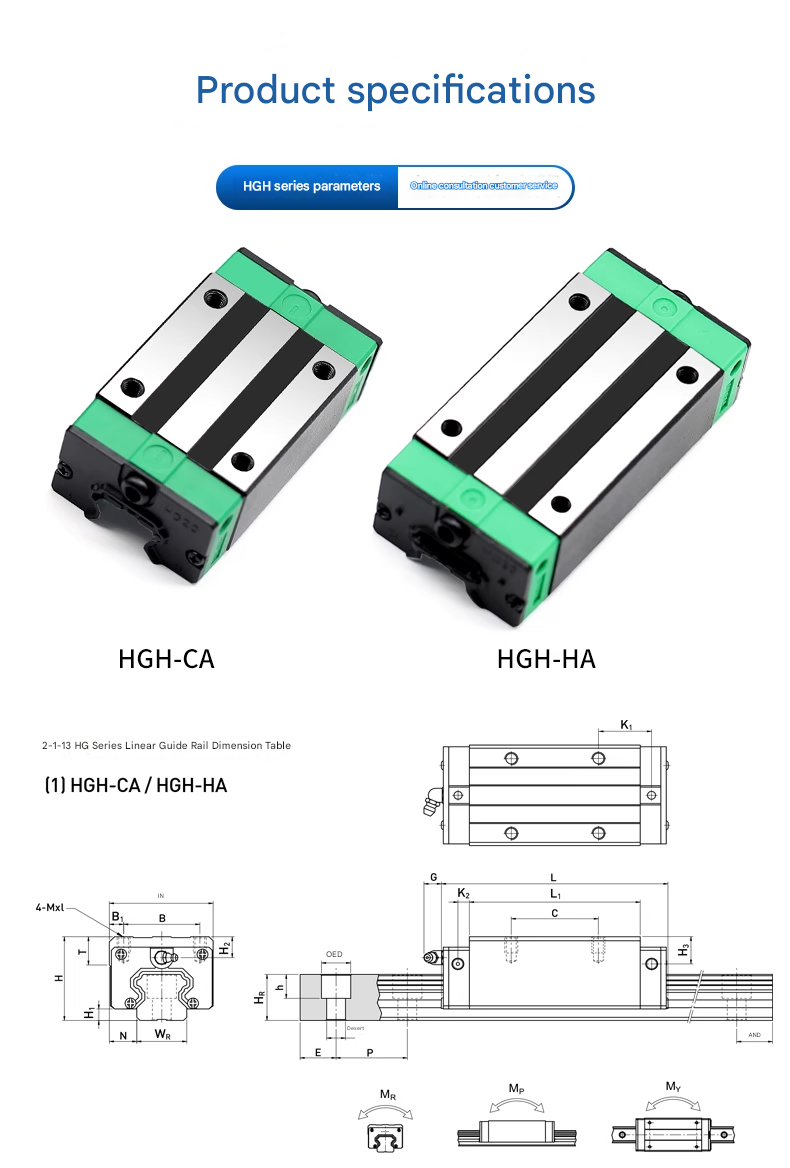

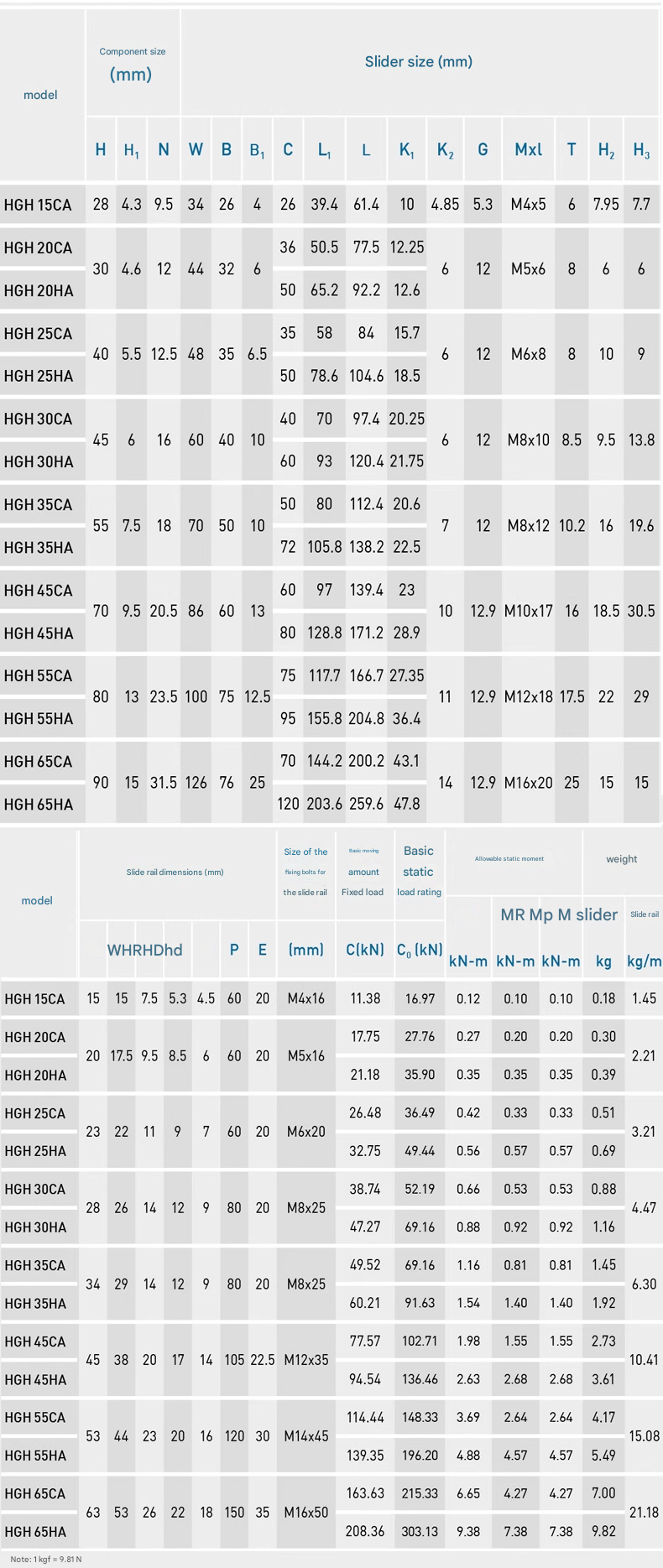

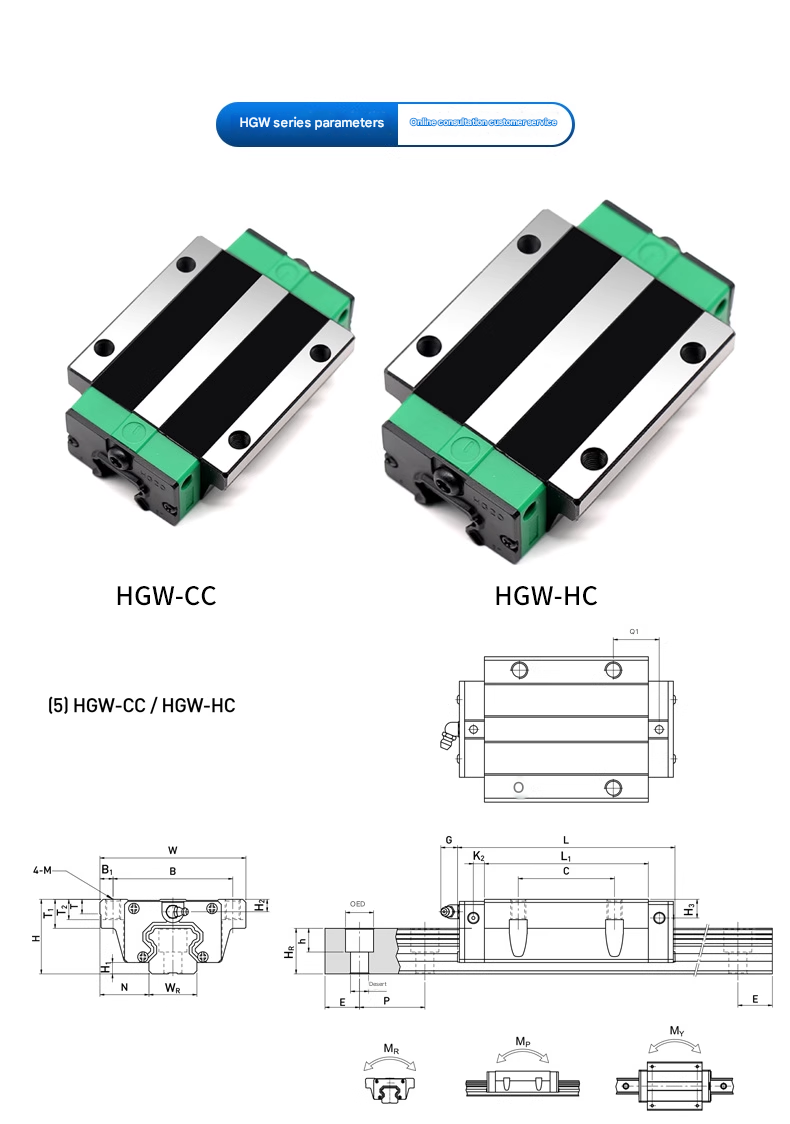

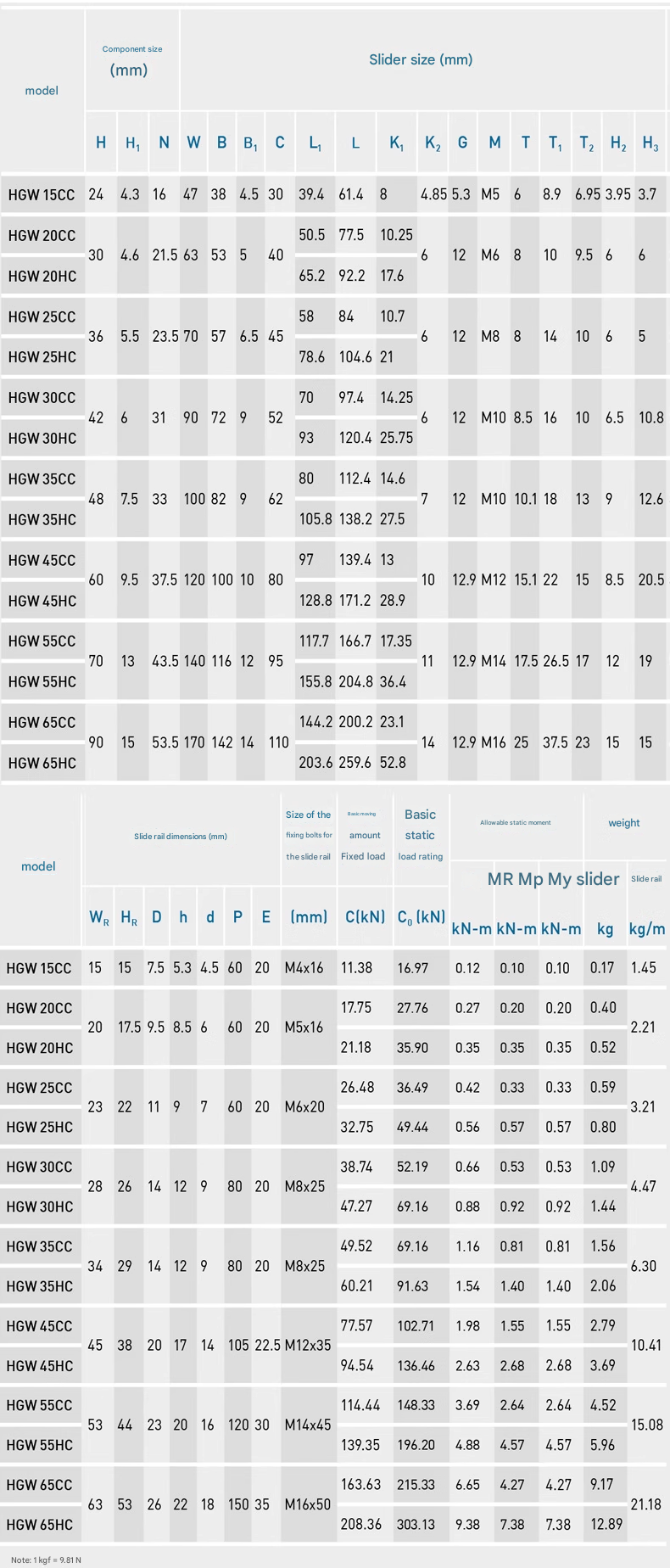

Product Specifications