Product Information

TBR linear guides are flanged rolling linear guides combining a polished shaft and an aluminum support, often referred to alongside SBR linear guides. They are commonly used low-cost guiding components in industry, with the following key features:

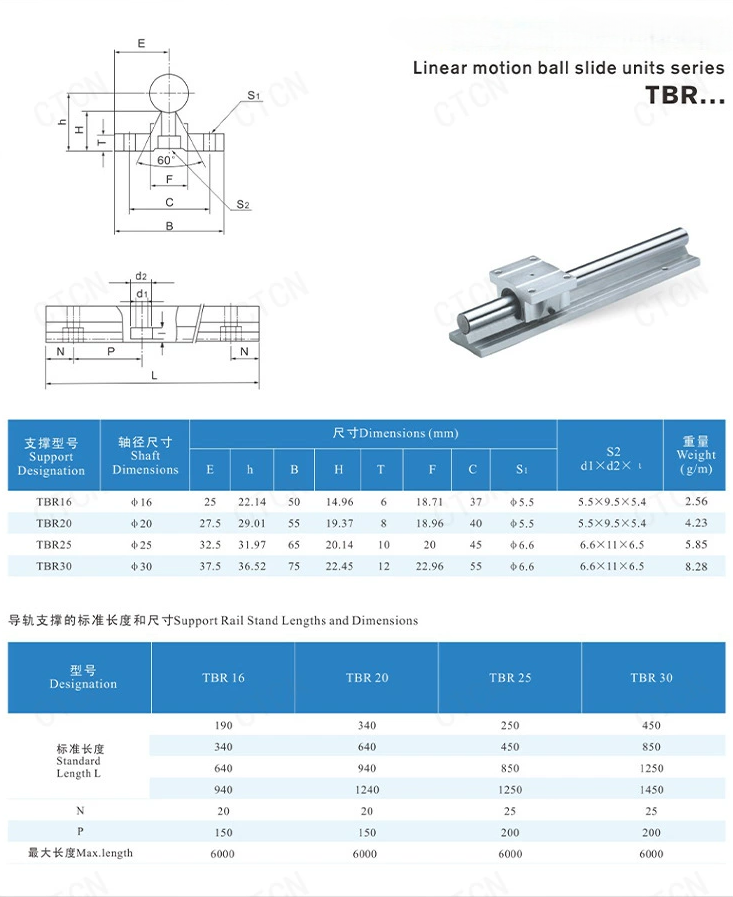

1. Core Structure and Materials: The main body consists of a G6 grade high-carbon steel polished shaft (hardness HRC58-64, hard chrome plated surface) and an anodized aluminum alloy support, paired with a flanged slider. The slider has through-holes for mounting screws. Common models include TBR16, TBR20, etc., with lengths up to 6000mm, and longer lengths can be achieved by joining multiple sections.

2. Outstanding Features: The flanged slider allows for both upward and downward mounting, offering more flexible installation than SBR guides which can only be mounted from above. The rolling friction coefficient is only 1/50 of that of sliding guides, resulting in high positioning accuracy and low wear, maintaining accuracy over the long term. The slider has a grease nipple, allowing for easy lubrication via a grease gun or automatic lubrication system, making maintenance convenient. The slider is also interchangeable with SBR guides, and its load-bearing performance is essentially the same as SBR guides.

3. Typical Application Scenarios: Due to their moderate cost and easy installation, they are suitable for applications requiring medium precision and load capacity. They are widely used in the linear motion guiding structures of woodworking machinery, printing equipment, CNC milling machines, and various automated conveyor lines.

Product Specifications