Product Information

Electroplated linear bearings are rolling/sliding type linear bearings with a surface treated by electroplating. The core is enhanced with an electroplated layer to improve rust and corrosion resistance. They are general-purpose precision linear guiding components, with the following key information:

1. Core Structure and Materials

- Main structure: The basic structure is the same as ordinary linear bearings (rolling type includes steel balls + cage, sliding type uses a composite bushing), and the ends often have flanges (round/square/chamfered) or a flangeless design;

- Electroplating process: The outer surface is mostly treated with zinc plating, nickel plating, or chromium plating (zinc plating focuses on rust prevention, nickel plating combines aesthetics and corrosion resistance, and chromium plating improves hardness);

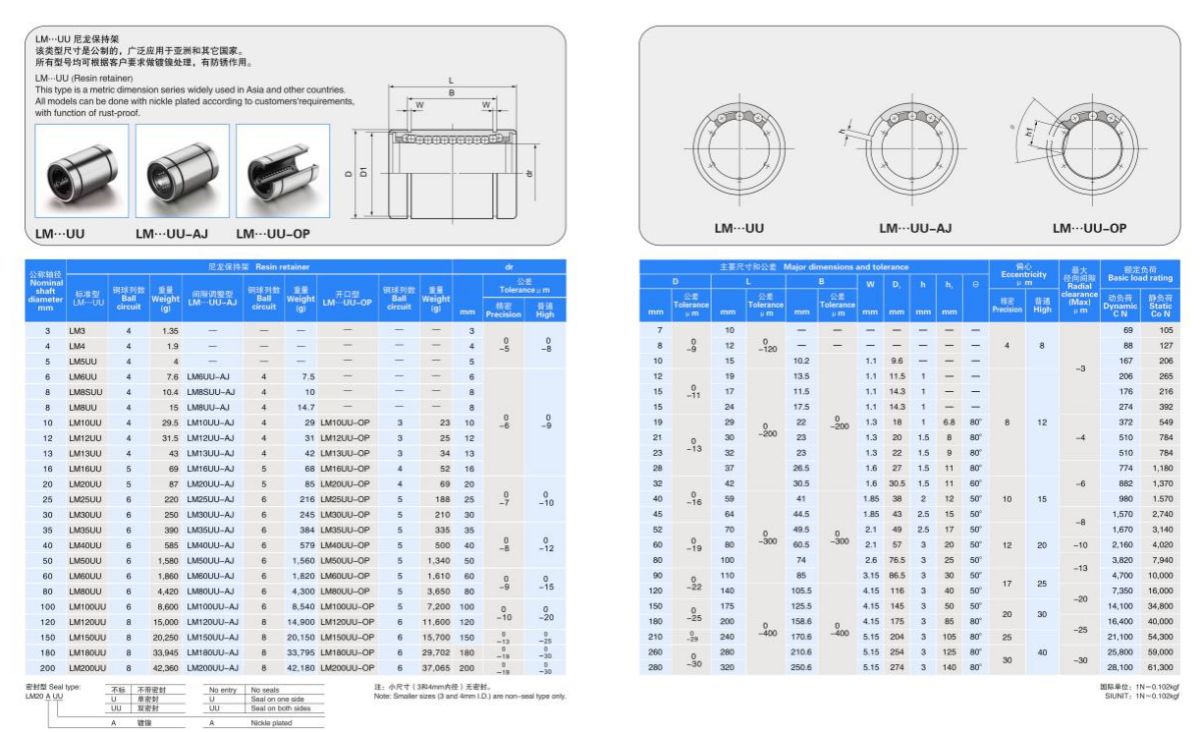

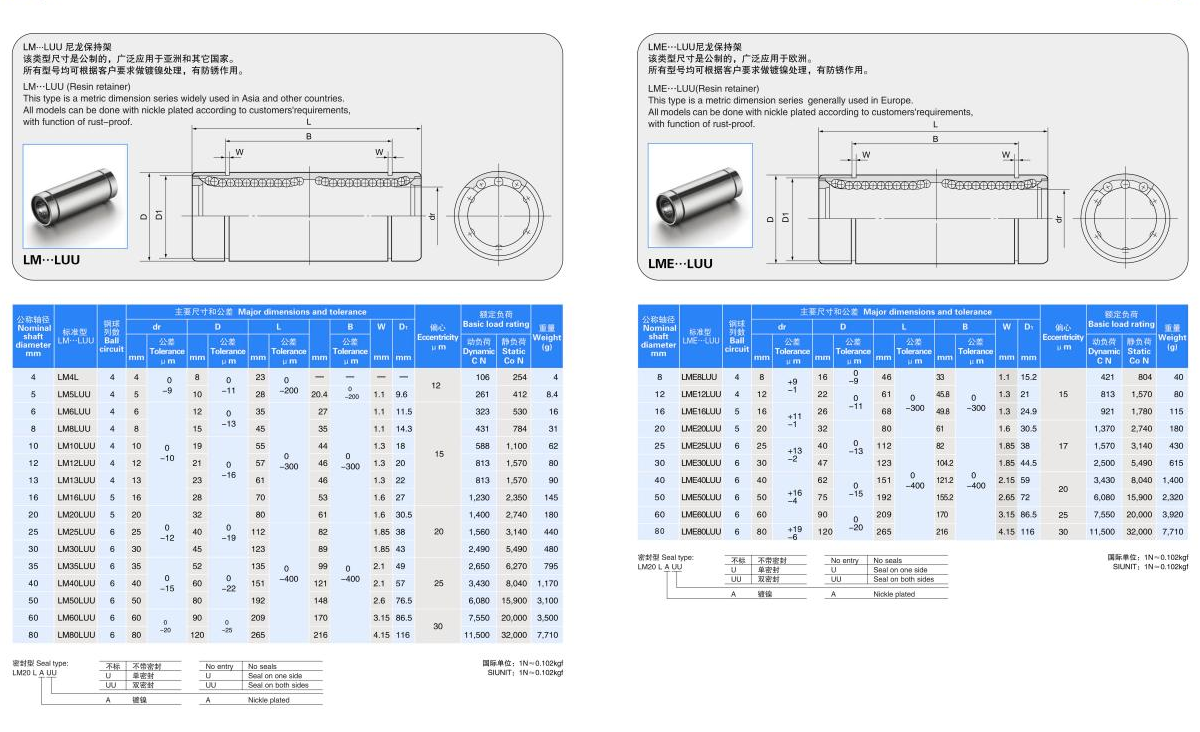

- Core materials: The body is made of bearing steel or carbon steel, the cage is commonly made of resin/steel, and the sliding type bushing contains bronze + PTFE coating. Suitable for shaft diameters of 6~60mm, represented by LM (basic linear) and LM...L (extended linear bearing) series models.

2. Key Features

- Advantages: The electroplated layer significantly improves rust and corrosion resistance, making it suitable for complex working conditions such as humid and dusty environments; low rolling friction coefficient (0.001~0.005), smooth operation and low noise; high degree of standardization, strong interchangeability, and convenient installation and maintenance;

- Limitations: Medium load capacity, rolling type has weaker impact resistance than sliding type, and is not suitable for ultra-high pressure and ultra-high speed extreme scenarios.

3. Typical Applications

Widely used in industrial applications such as automation equipment, CNC machine tools, 3D printers, and packaging machinery. Also suitable for medical equipment, food machinery, precision instruments, and other equipment requiring rust prevention and guiding accuracy. It is a highly versatile linear guiding component in industrial production.

Product Specifications