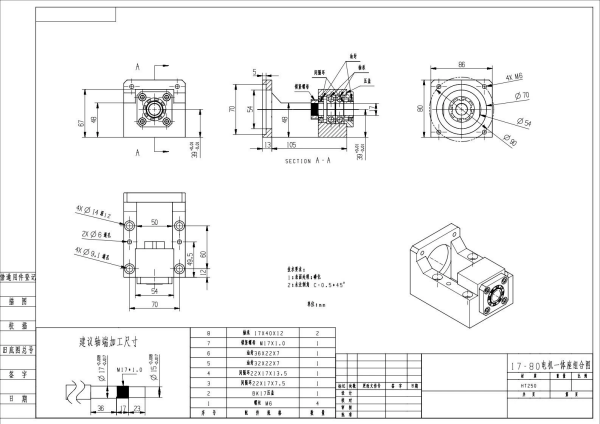

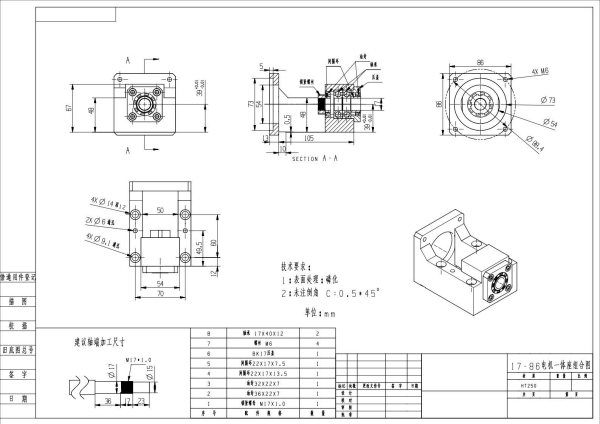

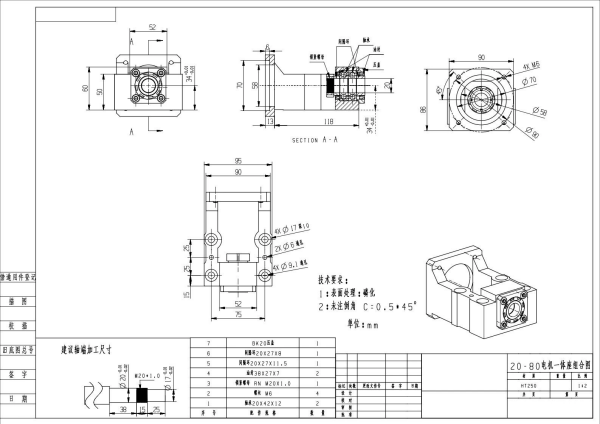

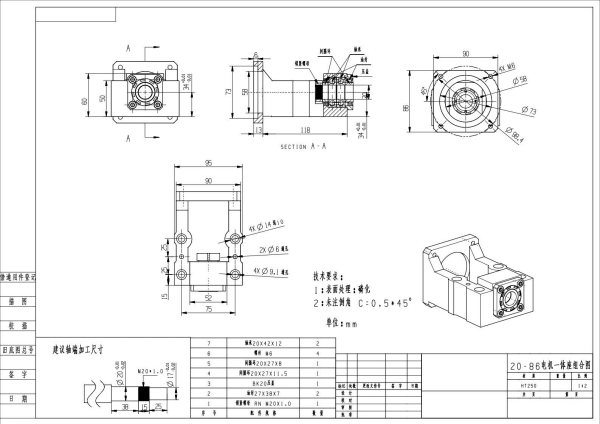

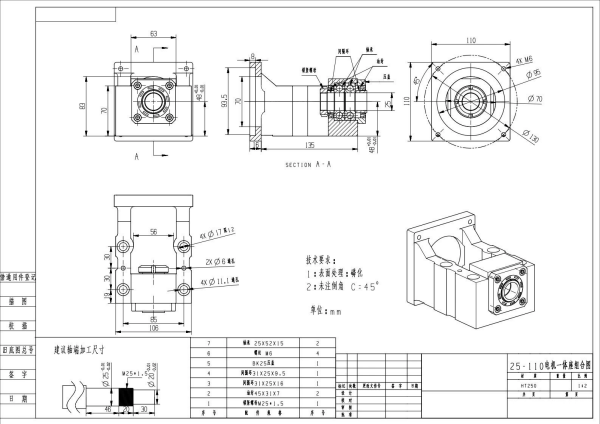

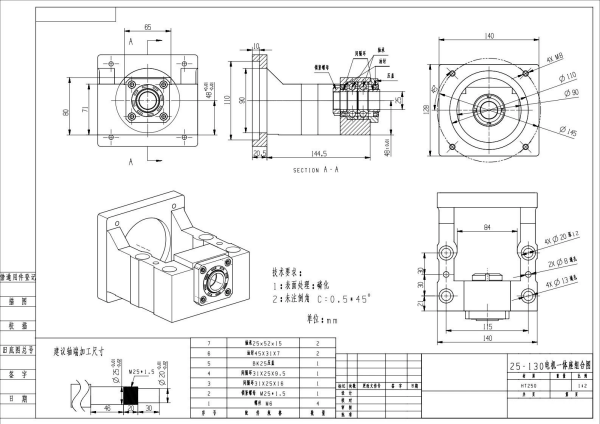

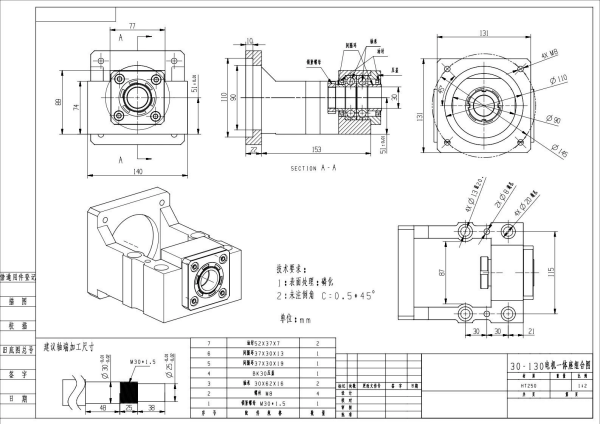

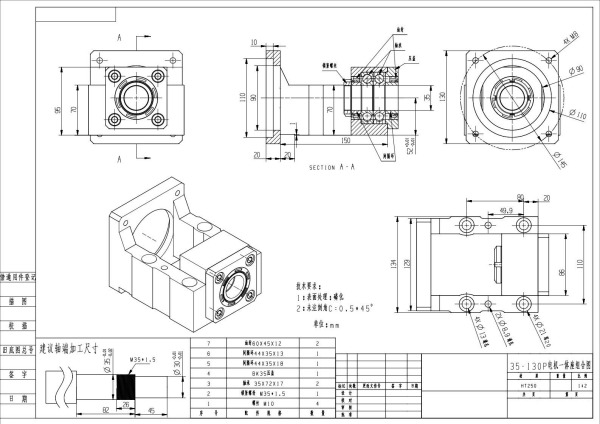

Product Information

Motor integrated bearing refers to a bearing component integrated into the motor housing, used to support the motor shaft and ensure its rotational accuracy. The following is an introduction to it:

Structural Features

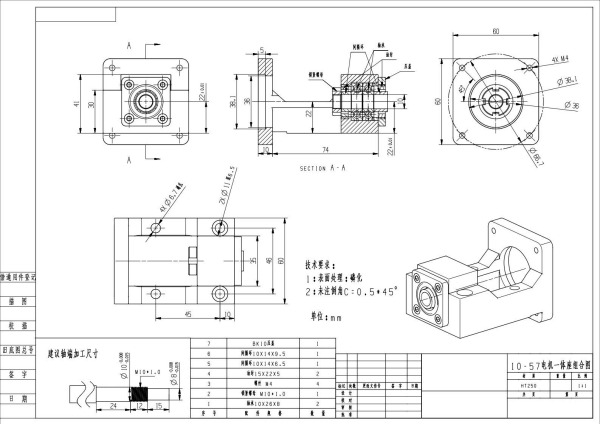

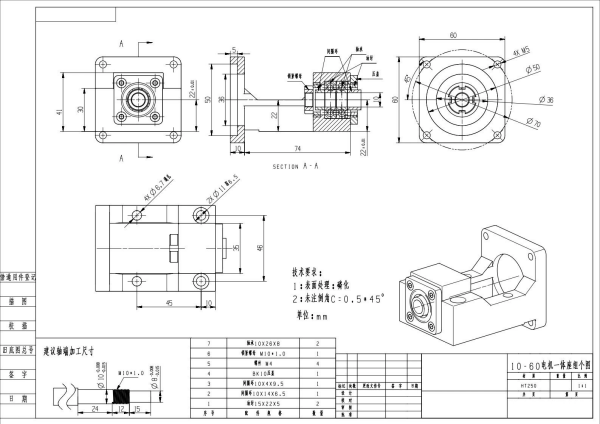

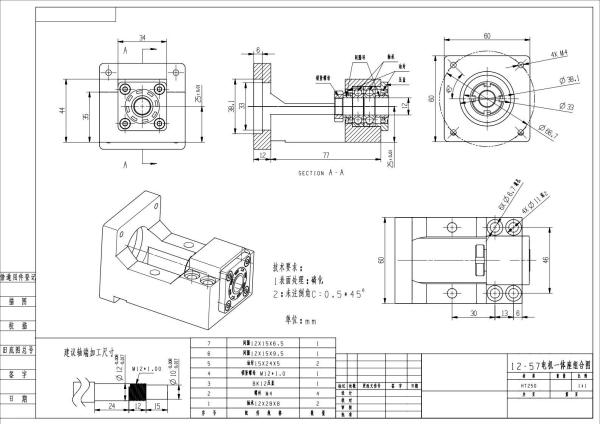

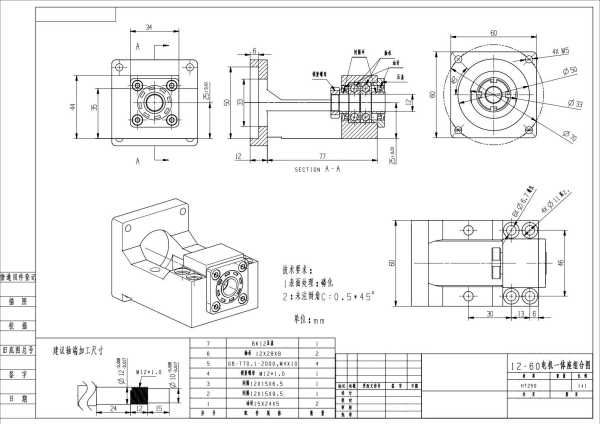

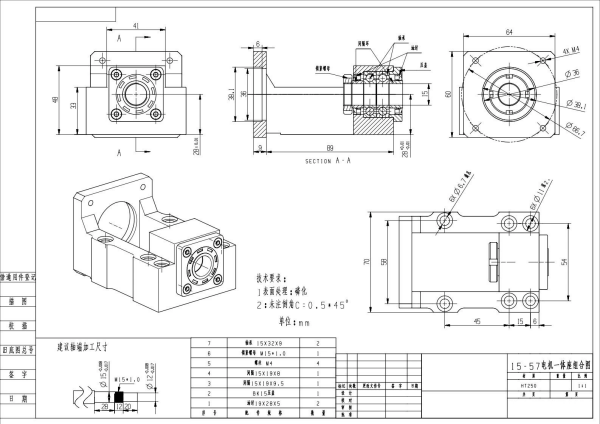

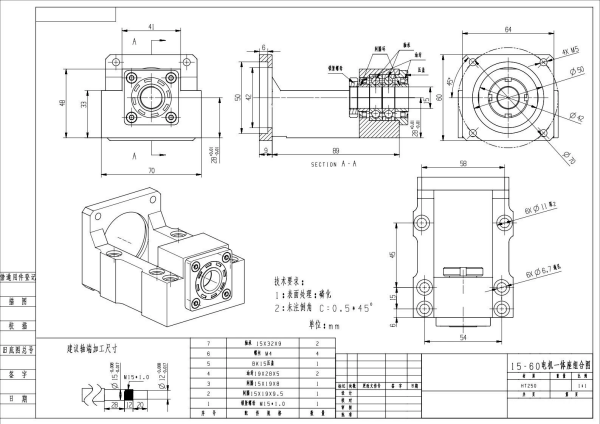

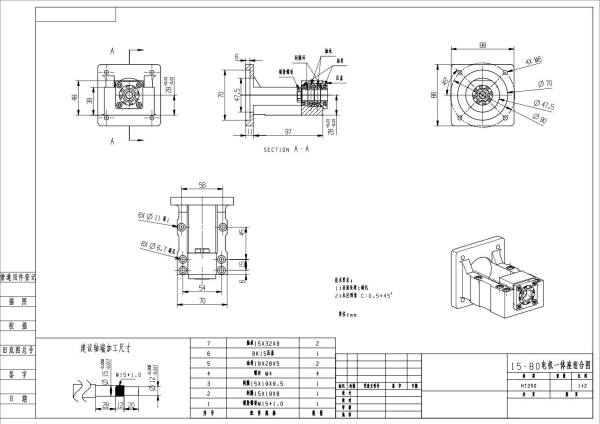

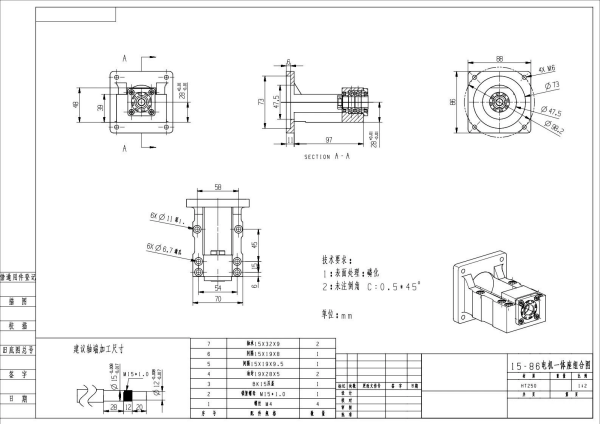

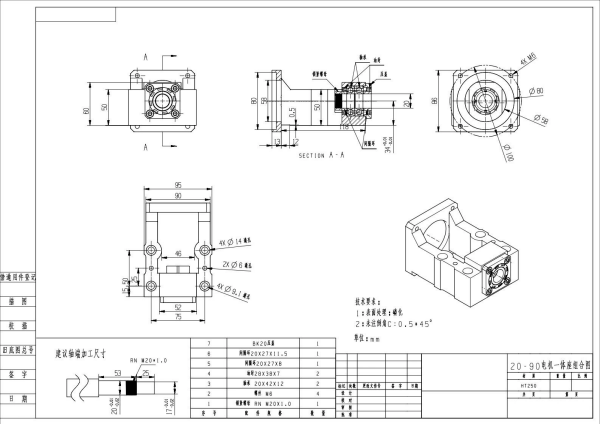

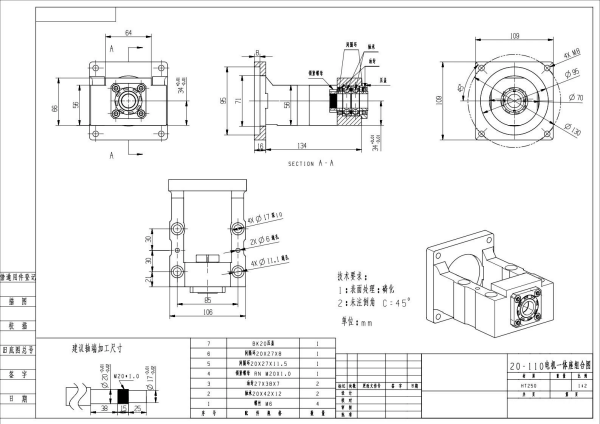

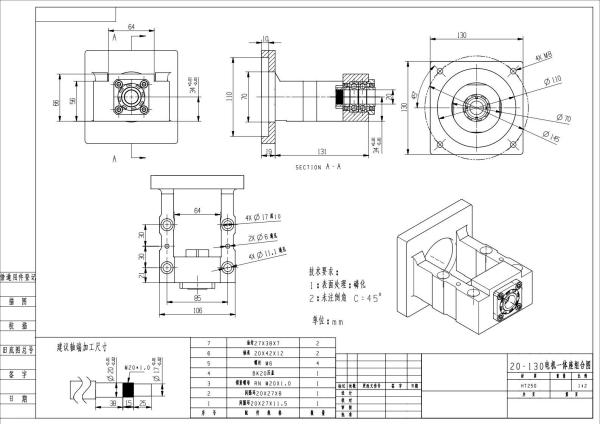

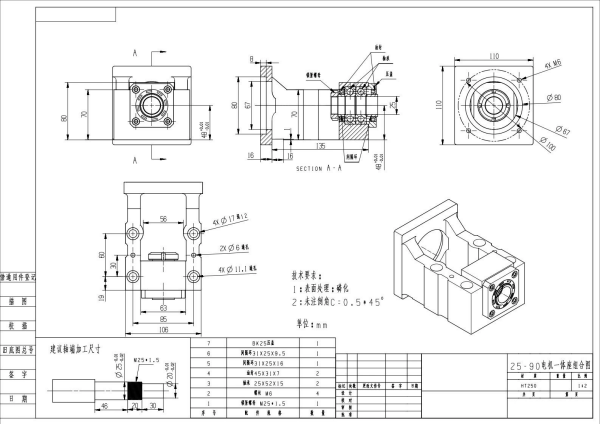

- Integrated Design: Some motor integrated bearings adopt an integrated structure, such as cross roller bearings. One end of the bearing inner ring is integrally formed with a connecting shaft, and the other end has a drive shaft, which can be directly connected to rotating components and permanent magnet rotors without the need for additional shaft assembly.

- Integrated Installation: The motor integrated housing usually integrates components such as the motor drive base, coupling, and support base. The bearing, as a key support component, works in conjunction with other components, reducing the number of installation parts and the accumulation of errors.

Common Types

- Mounted Ball Bearings: These integrate a ball bearing with a dedicated bearing housing. The outer ring surface is spherical, providing self-aligning capabilities to accommodate angular deviations between the shaft and the bearing housing mounting hole. They are easy to install, have good sealing performance, and are suitable for motor and gearbox output ends.

- Angular Contact Ball Bearings: Such as integrated double-row angular contact ball bearings, which have two recessed raceways on the inner side of the outer ring and the outer side of the inner ring, with rolling elements embedded within. They can withstand both radial and axial loads simultaneously, ensuring the rotational accuracy of the motor spindle.

- Deep Groove Ball Bearings: These can withstand radial loads and a certain amount of axial load, have a low friction coefficient, and high rotational speed, and are commonly used for general motor support.

Advantages and Characteristics

- Convenient Installation: The integrated design simplifies the installation process. The motor integrated housing only needs to be fixed to the equipment, reducing the complex steps of adjusting center height and eccentricity in traditional installations.

- High Precision: Equipped with a dedicated ball screw support base containing radial thrust bearings, it effectively controls the axial movement of the ball screw, achieving high positioning accuracy. Concentricity and perpendicularity errors can be controlled within ±0.02mm.

- High Rigidity and Durability: Usually manufactured from high-quality medium-carbon steel, it has good impact resistance and wear resistance, and can maintain stable operation under high-intensity working conditions.

Product Specifications