Product Information

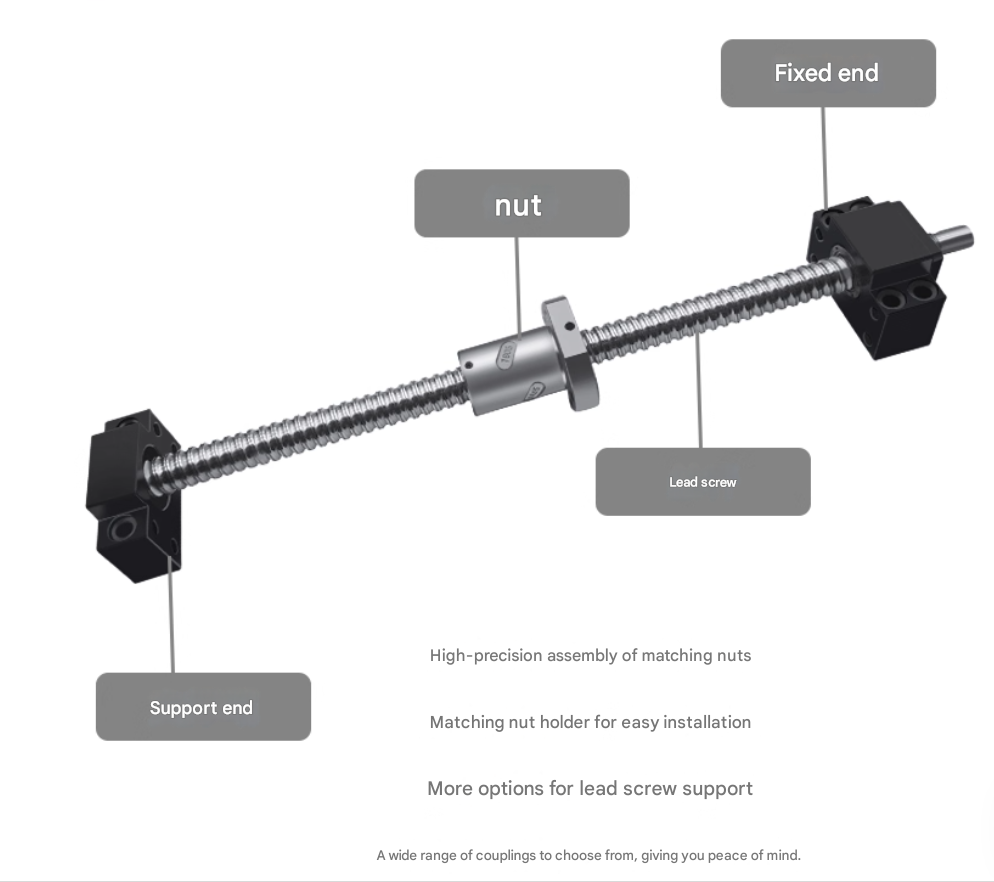

BK and BF bearings are commonly used in pairs as dedicated support bearing units for ball screws. The former is the fixed end, and the latter is the support end. Together, they ensure high precision and stability in ball screw transmission. Common paired models include BK10/BF10, BK20/BF20, etc. Key information is as follows:

1. BK Bearing (Fixed End): Features a high-precision angular contact ball bearing with pre-load adjustment. It can withstand both radial and bidirectional axial forces. It is pre-filled with lithium soap-based grease and equipped with special sealing washers, allowing for direct installation and long-term use. Its compact size is suitable for confined spaces. The material is mostly bearing steel or carbon steel, often with a black oxide surface treatment for rust prevention. It is compatible with C7-C5 precision grades and can meet the high-precision rotation requirements of CNC machine tools and other equipment.

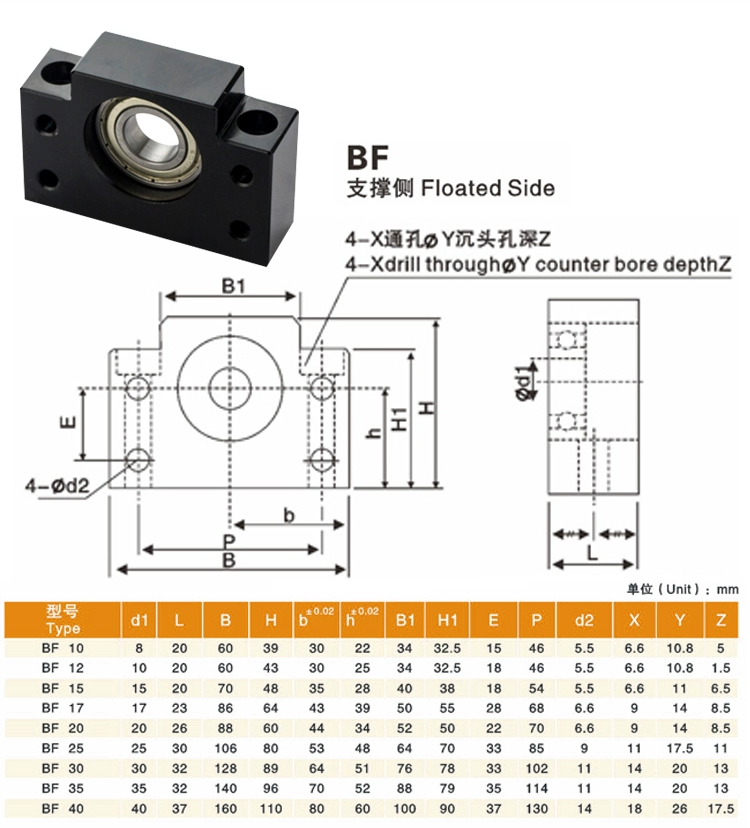

2. BF Bearing (Support End): Primarily uses deep groove ball bearings, mainly bearing radial forces and providing auxiliary support for the ball screw. It is also pre-lubricated and features a robust sealing design, allowing for assembly without additional adjustments. Square or round styles are available, and the material is similar to the BK bearing, with slightly lower processing costs. It is suitable for stable support scenarios under medium to low loads.

These two bearings are often used together for end support of ball screws and are widely used in equipment requiring precise linear motion, such as CNC machine tools, automated linear modules, packaging machinery, and printing equipment. During installation, the BK fixed end serves as the reference point, and the BF support end compensates for dimensional changes caused by thermal expansion and contraction, jointly ensuring the smooth operation of the ball screw.

Product Specifications