Product Information

I. Application Areas

1. Heavy-duty Automated Production Lines

Extended open-type slide blocks are widely used in lifting and guiding mechanisms for heavy workpieces (such as the sliding components of tooling fixtures in automotive welding production lines). Their extended structure distributes the load of heavy workpieces, preventing deformation caused by excessive stress at a single point; the open design facilitates quick replacement of the slide block without disassembling the long guide shaft, meeting the needs of frequent maintenance in production lines. For example, after adopting this slide block, the service life of the tooling fixture in a certain automotive assembly line increased by 30%, and the replacement time was reduced to one-third of the original time.

2. Logistics and Warehousing Equipment

In the telescopic forks of stacker cranes in automated warehouses and the heavy-duty lifting mechanisms of conveyor lines, extended open-type slide blocks can meet the requirements of long-stroke, high-load linear motion. Stacker crane forks need to slide on guide shafts several meters long, and the extended length of the slide block reduces shaking during high-speed movement; the open design facilitates installation and adjustment in narrow rack gaps, improving equipment maintenance efficiency.

3. Agricultural Machinery

In components such as the lifting and guiding mechanisms of combine harvester headers and the row spacing adjustment slide blocks of seeders, extended open-type slide blocks can adapt to complex conditions such as dust and vibration in agricultural environments. The extended structure enhances stability on bumpy roads, preventing "sticking" between the slide block and the guide shaft; the open design facilitates cleaning of accumulated dirt, straw, and other impurities, reducing failures caused by blockages.

4. Construction and Engineering Machinery

In the boom extension guiding mechanisms of concrete placing machines and the guide rail slide blocks of hydraulic lifting platforms, extended open-type slide blocks can withstand heavy loads and impacts. The extended section increases the contact area with the guide rail, reducing the pressure per unit area, and adapting to the frequent start-stop and heavy-load requirements in construction; the open structure facilitates quick replacement at the construction site, reducing equipment downtime. II. Advantages of Use

1. High Load Capacity and Stability

The extended structure increases the contact length between the slider and the guide shaft (or guide rail), resulting in a more even load distribution. This allows it to withstand larger radial loads than ordinary open sliders (typically a 30% to 50% increase), while reducing shaking and deviation during movement, thus improving overall stability.

2. Adaptability to Complex Working Conditions

The extended structure enhances tolerance for slight bending or installation errors of the guide shaft. Even with slight deformation of the shaft, the slider can maintain smooth movement. The open design facilitates the removal of dust, debris, and other impurities that may enter the interior, reducing wear and extending service life.

3. Strong Compatibility

As a standardized component, the dimensions of the extended open slider usually conform to general standards (such as the fit tolerance with linear shafts and guide rails). It is compatible with guide components from different brands, offering strong interchangeability and reducing the difficulty of matching parts during equipment upgrades or repairs.

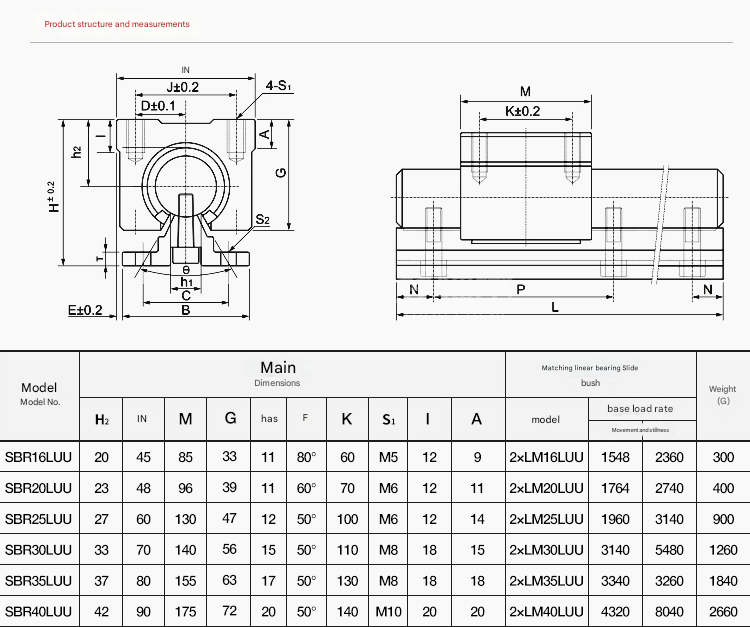

Product Specifications