Product Information

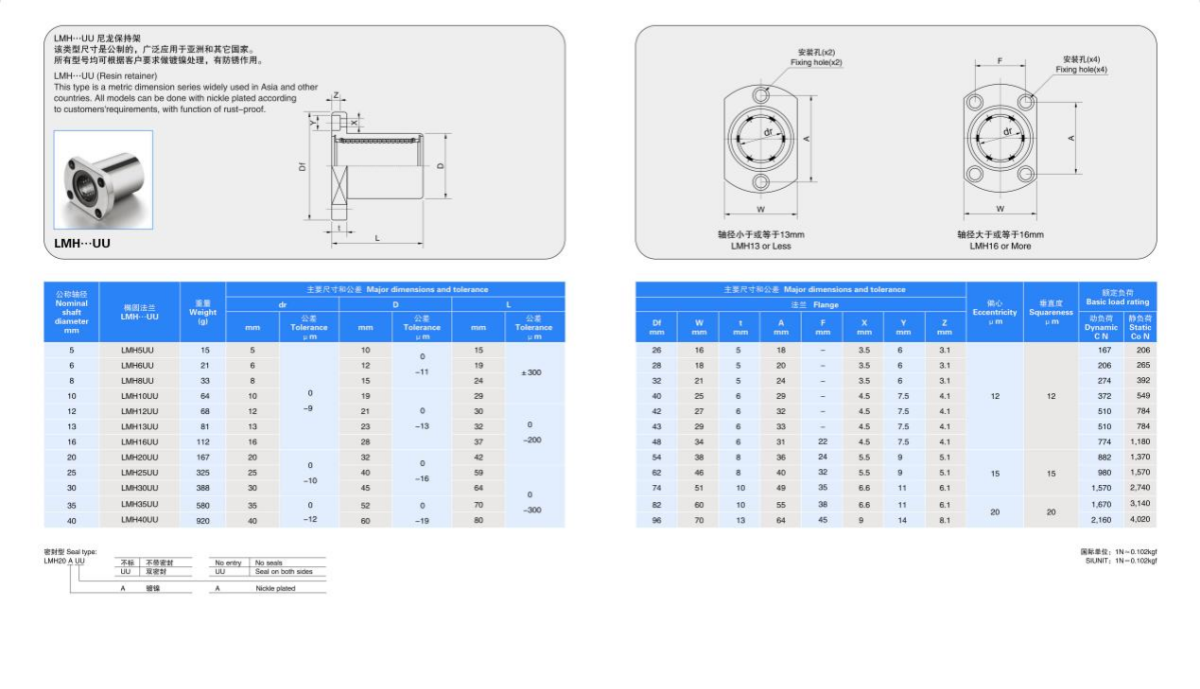

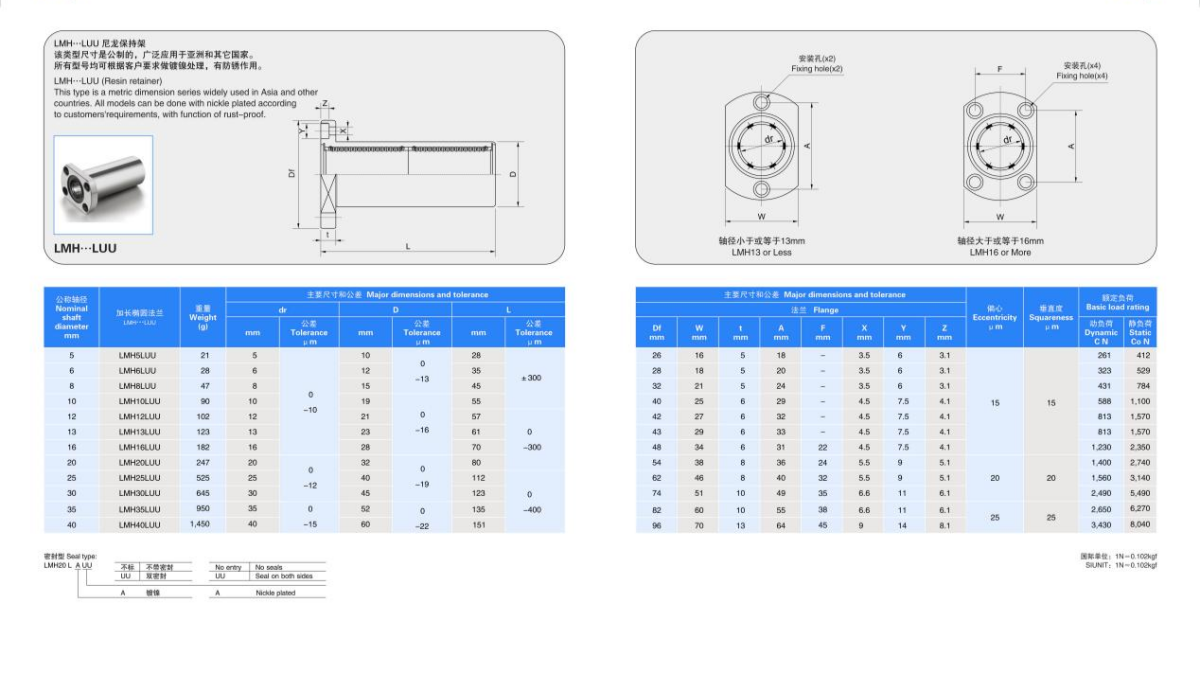

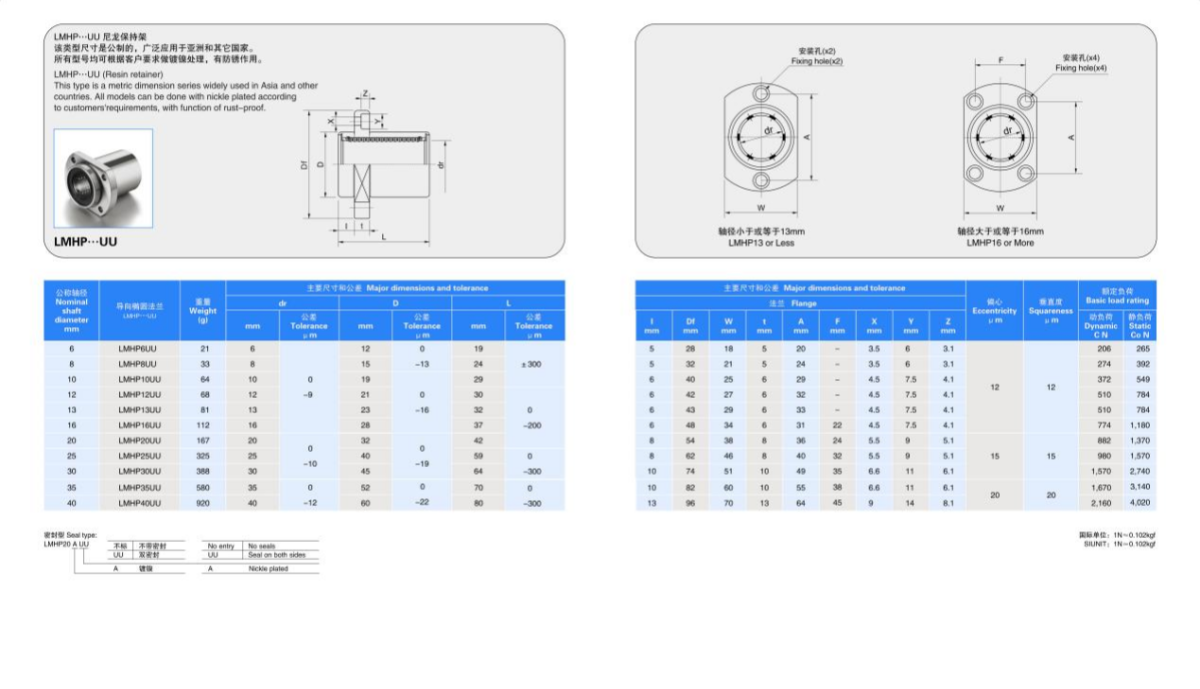

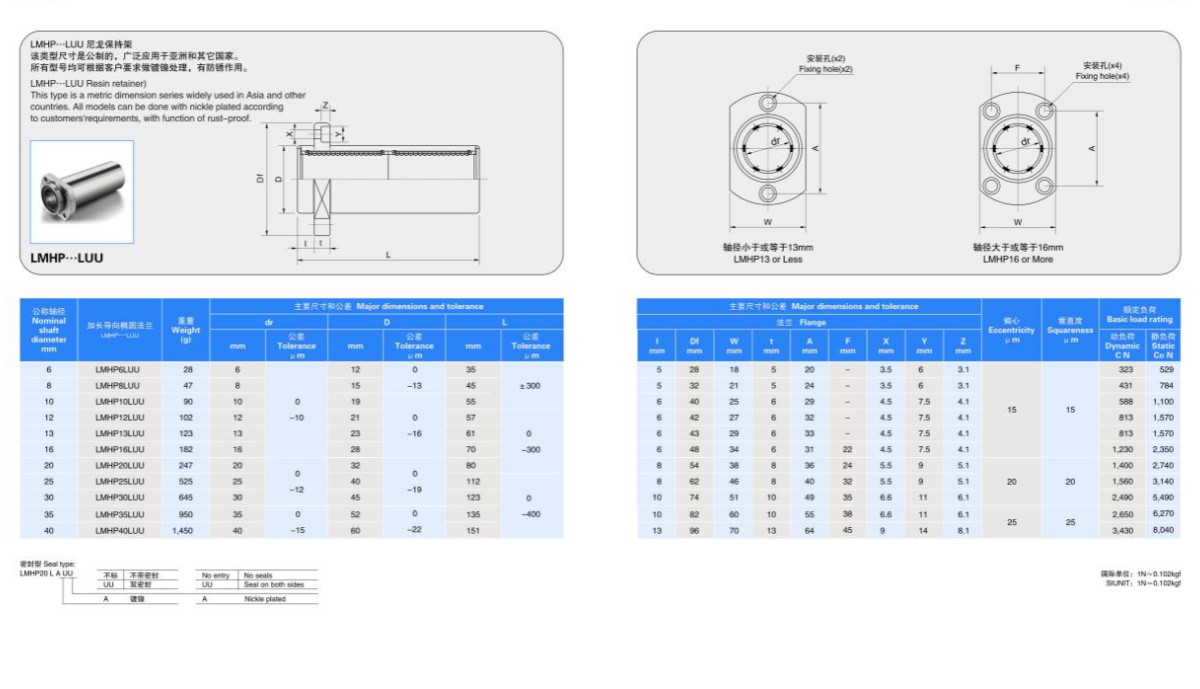

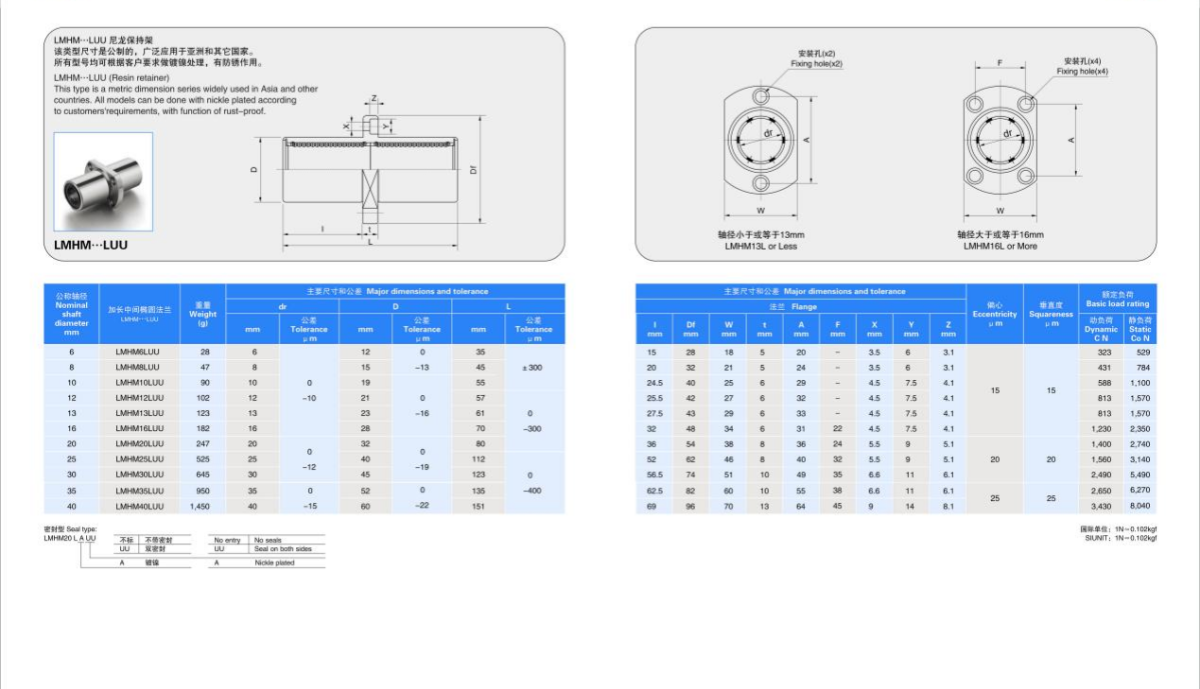

Flanged linear bearings with chamfered edges are mostly of an oval chamfered flange structure, with the surface treated by electroplating. Typical models include the LMH, LMH…L, LMHC, LMHC…L, LMHP, and LMHP…L series. They are suitable for precision linear guidance in space-constrained applications. Key information is as follows:

1. Structure and Material: The main body consists of a bearing steel outer shell, a resin cage, and steel balls. The ends have oval chamfered flanges with 2 or 4 mounting holes for quick screw fixing. The outer shell is electroplated with zinc, nickel, etc., and some models are equipped with rubber sealing covers. They are available for shaft diameters ranging from 6 to 60mm. For example, the LMH25LUU model has an outer diameter of 40mm, and other lengths such as 59mm and 112mm are also available.

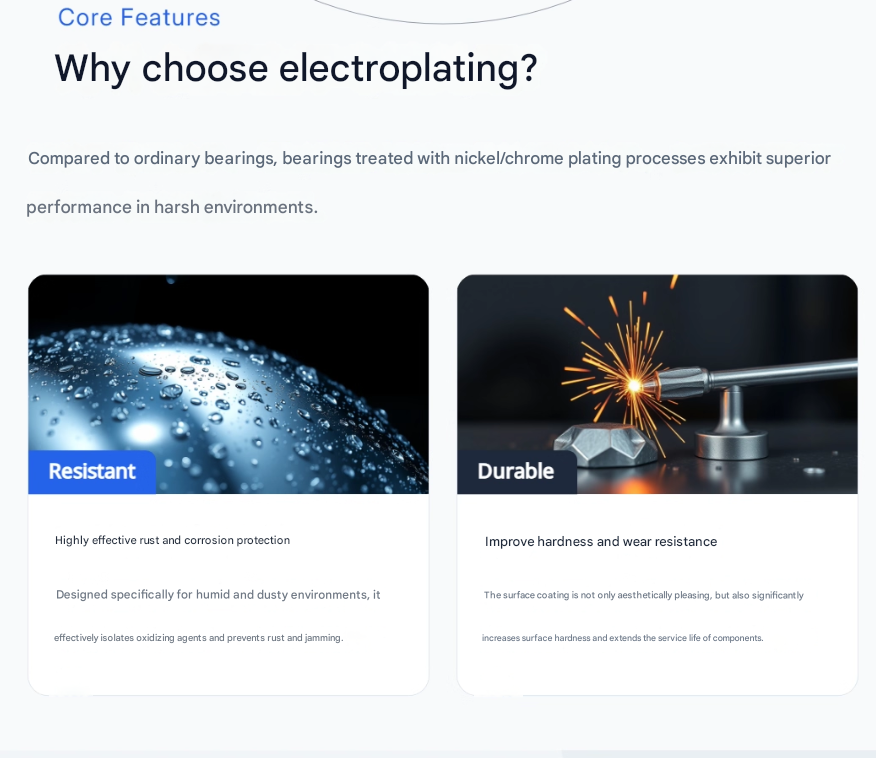

2. Core Features: The electroplated layer significantly improves rust and corrosion resistance, making them suitable for humid, dusty, and other corrosive working conditions. The chamfered flange saves more installation space than a round flange, making them suitable for compact equipment structures. They also have a low coefficient of friction, smooth operation, and low noise. As standardized components, they have strong interchangeability and are easy to maintain and replace. However, the point contact structure results in weaker load capacity and impact resistance.

3. Typical Applications: Widely used in brick and tile machinery, robotic palletizers, tunnel kilns, and other equipment. They are also suitable for automated slides, 3D printers, and small CNC auxiliary components. They are very common in small and medium-sized automated equipment that requires both installation space efficiency and guidance precision.

Product Specifications