Product Information

I. Application Areas

1. Optical Instruments: In optical instruments such as microscopes, telescopes, and laser processing equipment, vertical optical axis supports are used to support and fix optical components such as lenses and mirrors, ensuring the precise relative positioning between them. This guarantees the accuracy and stability of the optical path, enabling precise optical imaging, laser transmission, and other functions.

2. Semiconductor Manufacturing: In semiconductor manufacturing processes, such as photolithography machines and chip packaging equipment, high-precision linear motion and positioning are required. Vertical optical axis supports can be used to support and guide the optical axis, providing a precise positional reference for processes such as photolithography, etching, and packaging in chip manufacturing, ensuring the manufacturing precision and quality of semiconductor devices.

3. Office Equipment: For example, in vertical computer monitor stands, vertical optical axis supports allow for flexible adjustment of the monitor's height and angle, meeting different user needs and improving office comfort and efficiency. It also helps save desktop space.

II. Advantages of Use

1. High-Precision Positioning: The optical axis itself has high linearity and precision. Vertical optical axis supports can accurately support and fix the optical axis, ensuring that the cooperating optical components or mechanical parts can achieve high-precision positioning and movement, with accuracy reaching micrometers or even nanometers.

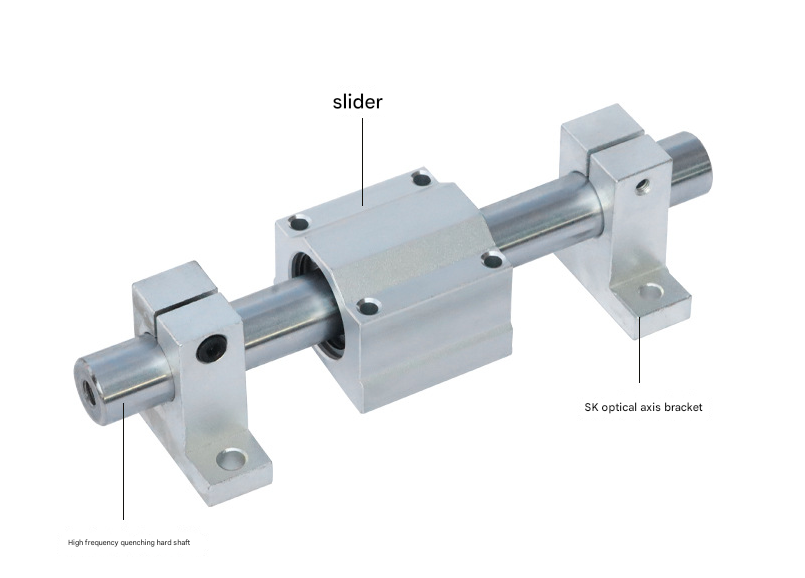

2. Compact Structure: The design of vertical optical axis supports is usually compact, occupying minimal space, making them suitable for use in equipment or work environments with limited space. This helps improve the integration and space utilization of the equipment, making the entire system more concise and efficient.

3. Easy Installation and Maintenance: The installation process of vertical optical axis supports is relatively simple. They can generally be quickly installed onto equipment or workbenches using bolt connections or other fixing methods. Maintenance is also convenient; routine checks and maintenance, such as cleaning and lubrication, are sufficient to ensure normal operation and performance.

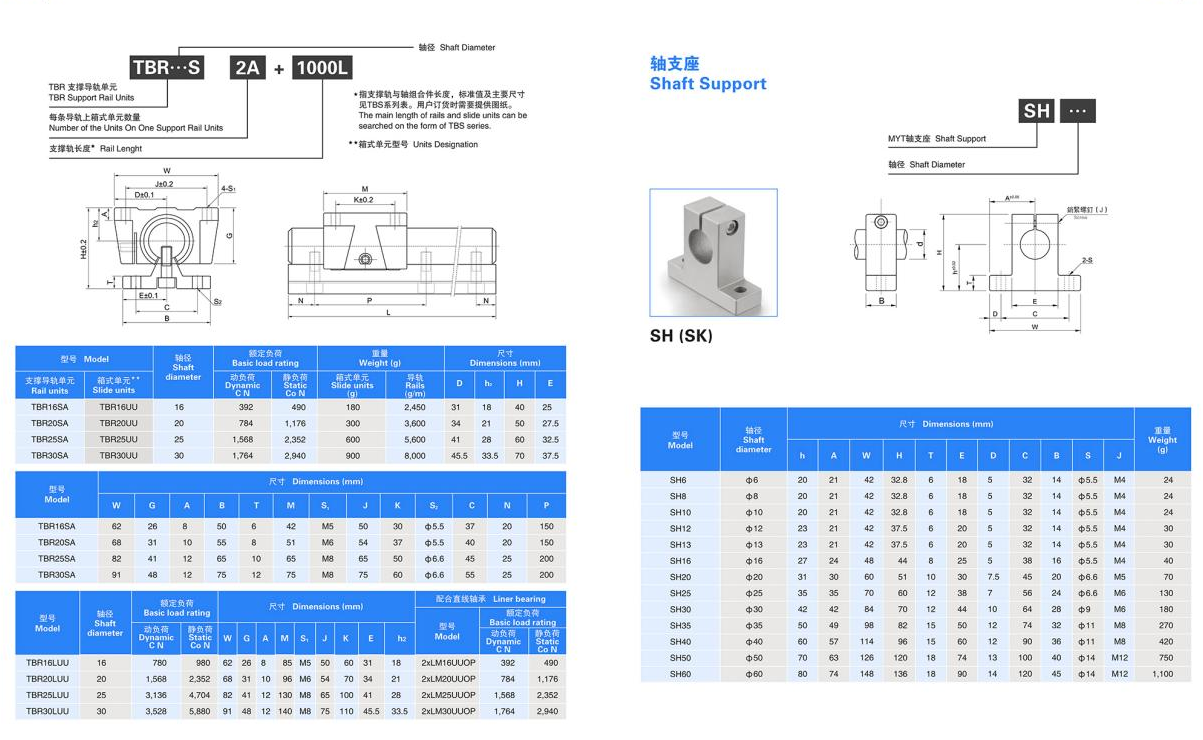

Product Specifications