Product Information

Split retaining rings, also known as split locking rings, are detachable standard fasteners for shafts. Their primary function is to secure bearings, gears, and other components on a shaft to prevent axial displacement. Key information is as follows:

1. Structure and Material: The ring is detachable into two halves, secured by two hex socket screws. This offers greater flexibility in installation and maintenance compared to open-type retaining rings. Materials include carbon steel, 304 stainless steel, and aluminum alloy. Carbon steel is often galvanized or nickel-plated for corrosion resistance, and aluminum alloy is typically anodized. Some models include polyurethane cushioning pads to reduce metal impact noise. Common metric inner diameters range from 3 to 100 mm, and imperial sizes from 1/8 inch to 4 inches, conforming to standards such as DIN 705 and ISO 6432.

2. Key Features: They can be installed and adjusted without disassembling other components on the shaft, making them suitable for post-assembly applications. They provide strong clamping force with minimal damage to the shaft. Some models are suitable for special environments such as vacuum conditions, and others reduce contact damage between components. However, their load capacity is limited and they are not suitable for extreme transmission scenarios involving ultra-high pressure or ultra-high speed.

3. Typical Applications: Suitable for shaft positioning in general machinery, widely used in motors and gearboxes to position rotors and gears. They are also commonly used in automation equipment, conveyor lines, and automotive transmission components. Stainless steel versions are suitable for humid and corrosive working environments.

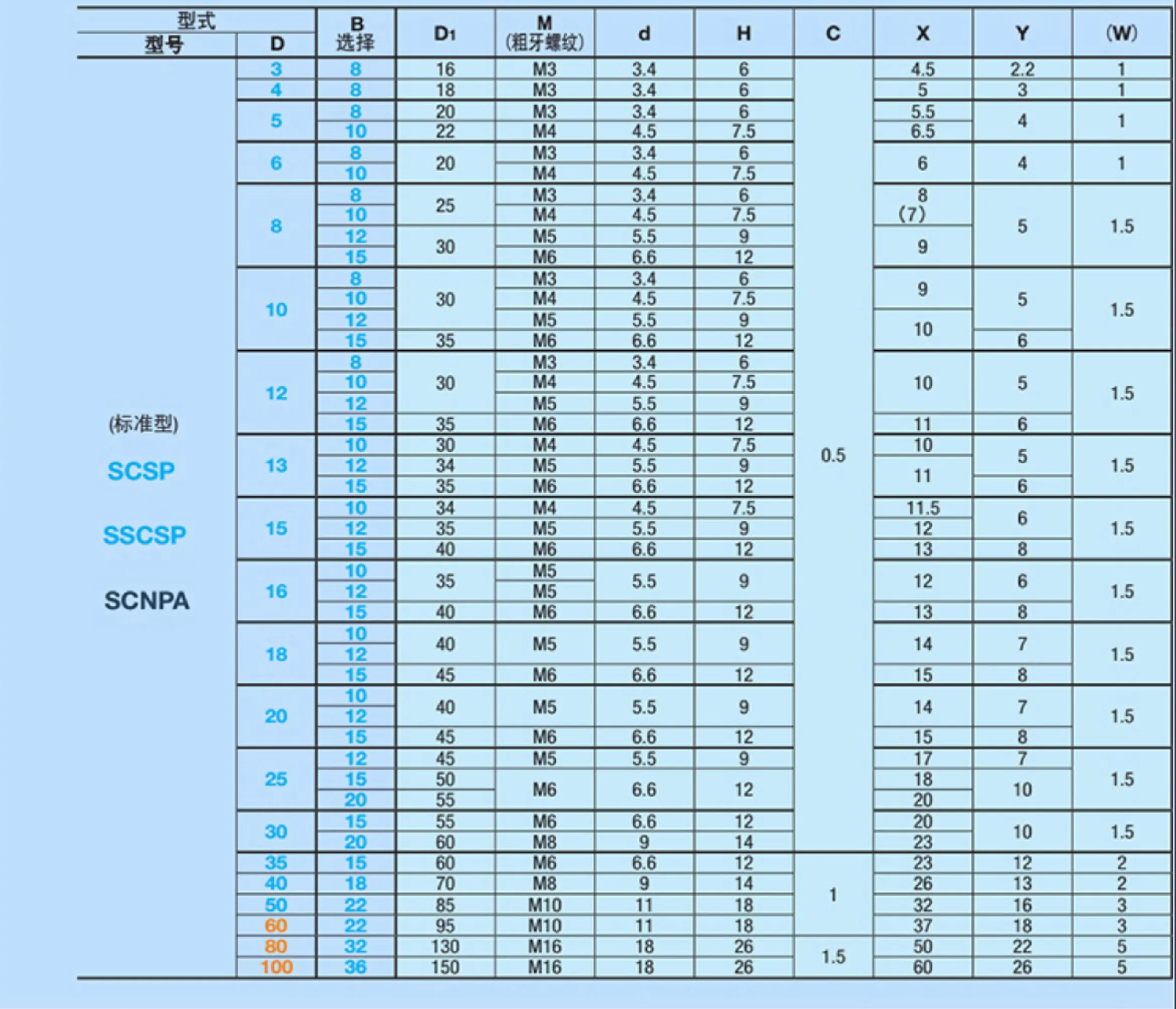

Product Specifications